Advantages

Of Fingerprint-Free Colored Stainless Steel Sheets for the Kitchen and Bathroom

Industry

In recent years, due to the wide application of stainless steel in the kitchen and bathroom industry, more beautiful and durable products have appeared on the market. However, due to the application characteristics of the kitchen and bathroom industry, ordinary colored stainless steel plates are easy to stick to oil stains and difficult to clean, so they cannot be fully used in the kitchen and bathroom field. With the development of fingerprint-free colored stainless steel sheets, the application in the kitchen and bathroom fields has reached a new level. XTT has introduced fingerprint-free color stainless steel technology, and gained a good reputation in the industry.

Fingerprint-free

colored stainless steel sheet refers to coating a protective layer of

transparent colorless to light yellow liquid on the surface of colored

stainless steel decoration. After this transparent nano-metal roller coating

liquid dries, it is combined with colored stainless steel decoration of various

textures. The board surfaces are firmly bonded together to form a transparent,

hard and solid protective film layer. The processing technology of colored

stainless steel fingerprint-free sheets will affect the long-lasting

aesthetics, pollution resistance, corrosion resistance and friction resistance

of the metal plates.

Various colored

stainless steel products can be processed through advanced fingerprint-free

technology to increase the beauty and durability of metal decorative panels.

The main purpose is to prevent people from leaving fingerprints on the surface

when touching these panels, so as not to be stained with oil, sweat, dust, etc.

tarnishes the surface. At present, the price of metal decorative panels that

have been specially processed without fingerprints is generally not very high,

and their aesthetics and value are relatively cost-effective, effectively

improving the decorative effect. The price of fingerprint-free boards is also

related to the thickness of colored stainless steel. Generally, the thicker the

board, the more expensive it is.

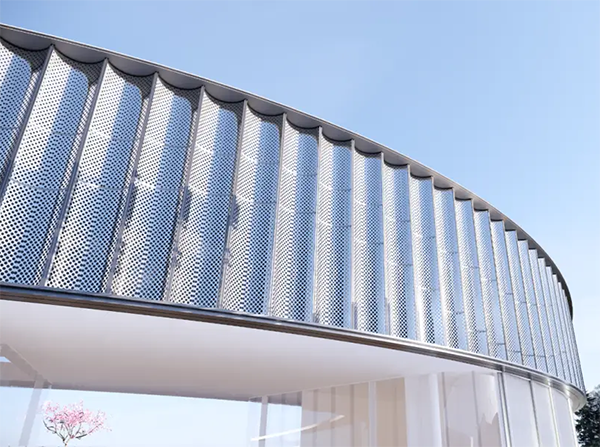

Fingerprint-free

colored stainless steel plates are mainly used for decoration, and can be used

in hotel decoration, KTV, elevators, furniture, security doors, spacecraft,

lighting, building decoration, etc. The fingerprint-free processing will not

damage the appearance of the base layer. At the same time, the colored film

layer will not peel off, and stains can be completely removed by wiping with a

dust-free cloth. Fingerprint-free boards generally first select high-quality

stainless steel sheets, and then process them through dozens of processes such

as shearing, pressing, bending, forming, welding, oiling, and sandblasting to

form various colored stainless steel decorative boards. Finally,

fingerprint-free treatment is performed on the surface.

What Are the

Advantages of Fingerprint-Free Processing On Colored Stainless Steel Surfaces?

v It is easy to clean surface stains and does

not require metal cleaning agents. Some chemicals will make the stainless steel

sheet black; it is not easy to stick to fingerprints and dust, has a delicate

hand feel, and has super fingerprint and anti-fouling effects.

v The fingerprint-free transparent film layer

can protect the metal surface from being easily scratched, because the gold

plating oil on the surface has good film properties, high hardness, and is not

prone to peeling, powdering, yellowing, etc.

v It has a strong appearance and texture, has

an oily moistness, a soft hand feel, and retains a good metallic texture.

v The fingerprint-free board changes the cold

and dull characteristics of metal and looks warm, elegant and decorative.

v The colored stainless steel

fingerprint-free sheet has excellent anti-rust properties. It forms a

protective film on the metal surface to effectively block external erosion of

the metal interior, greatly extending its service life.

This kind of

fingerprint-free board also has its disadvantages, that is, it cannot be welded

and stretched, and it will turn black when exposed to high temperatures,

seriously affecting its aesthetics.

And you should

also pay attention to some things when installing. Try to avoid construction in

rainy or high-humidity weather. It is forbidden to operate with water. When

using the non-fingerprint board for the first time, you can try it on a small

area now. If the effect is good, then use it on a large area. The transparent

film layer is easily affected by high temperatures, so it should be constructed

away from fire sources.