What Is

Perforated Sheet?

A perforated

sheet is a metal sheet that has been punctured with a series of holes in a

pattern. These holes can vary in size, shape, and distribution, depending on

the intended application. Perforated sheets are commonly made from materials

such as stainless steel, aluminum, or galvanized steel.

Perforated

sheets serve a variety of purposes across different industries. They are widely

used for different applications:

l Filtration: Perforated

sheets are used as screens or filters to separate solids from liquids or gases.

They can be found in industries such as oil and gas, water treatment, and food

processing.

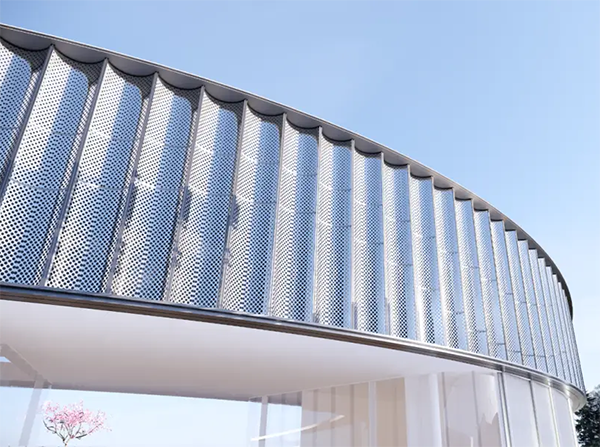

l Ventilation: Perforated

sheets are used to allow airflow while still providing protection or

containment. They are commonly used in HVAC systems, automotive components, and

architectural elements.

l Acoustics: Perforated

sheets can be used as acoustic panels to absorb or block sound waves. They are

often installed in theaters, recording studios, and noisy industrial

environments.

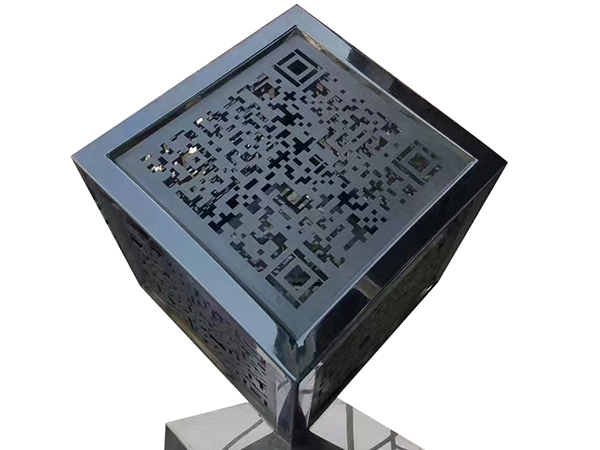

l Decoration: Perforated

sheets can be used for aesthetic purposes in architectural design, interior

decoration, and furniture manufacturing. The patterns created by the

perforations can add visual interest and texture to surfaces.

l Safety: Perforated

sheets are sometimes used as safety barriers or guards to prevent access to

hazardous areas or machinery while still allowing visibility and airflow.

Overall,

perforated sheets offer versatility, strength, and functionality, making them a

popular choice for a wide range of applications in various industries.

Today, let’s see

how important perforate sheets play role in decoration industry.

Nowadays

perforated sheets become more and more important in the decoration industry due

to their versatility, functionality, and aesthetic appeal. And they keep some

advantages as below:

Ø  Design

Flexibility: Perforated sheets offer immense design flexibility,

allowing for the creation of intricate patterns, shapes, and designs. They can

be customized to suit specific design requirements, making them ideal for

decorative purposes.

Design

Flexibility: Perforated sheets offer immense design flexibility,

allowing for the creation of intricate patterns, shapes, and designs. They can

be customized to suit specific design requirements, making them ideal for

decorative purposes.

Ø Visual

Appeal:

Perforated sheets add visual interest to various decorative applications. They

can be used to create visually striking features such as decorative screens,

partitions, wall panels, and facades. The patterns and designs created through

perforation can enhance the overall aesthetics of a space.

Ø  Lighting

and Acoustic Control: Perforated sheets are often used in

lighting fixtures and acoustic panels. They allow for the passage of light and

sound while providing a decorative element. By controlling the distribution of

light and sound, perforated sheets contribute to creating a more visually

appealing and acoustically comfortable environment.

Lighting

and Acoustic Control: Perforated sheets are often used in

lighting fixtures and acoustic panels. They allow for the passage of light and

sound while providing a decorative element. By controlling the distribution of

light and sound, perforated sheets contribute to creating a more visually

appealing and acoustically comfortable environment.

Ø Ventilation

and Airflow: In architectural and interior design, perforated sheets

are utilized for ventilation purposes. They are commonly used in HVAC systems,

ceilings, and walls to facilitate airflow while maintaining a decorative

appearance.

Ø Privacy

and Security: Perforated sheets can be employed to provide privacy

and security without sacrificing aesthetics. They are often used in fencing,

gates, and window coverings, allowing for airflow and visibility while creating

a decorative barrier.

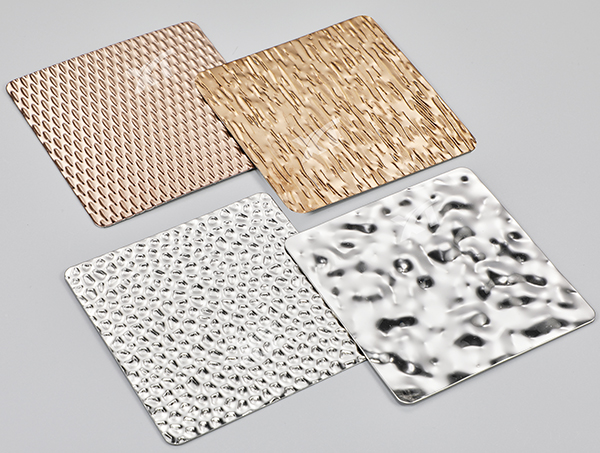

Ø Material

Variety:

Perforated sheets are available in a wide range of materials including metals

like aluminum, stainless steel, and copper, as well as plastics and composites.

This variety of materials expands their applications in decoration, catering to

different design styles and requirements.

Ø Durability

and Maintenance: Depending on the material used, perforated sheets can

offer durability and ease of maintenance, making them suitable for both indoor

and outdoor decorative applications. Materials like stainless steel and

aluminum are corrosion-resistant and require minimal upkeep.

Overall,

perforated sheets are essential in the decoration industry for their ability to

combine functionality with decorative appeal, offering endless possibilities

for creative design solutions.

What's The Difference Between Stainless Steel Perforated

Sheet And Aluminum Perforated Sheet?

Stainless

steel perforated sheets and aluminum perforated sheets are both popular

materials used in various industries for their perforated sheet applications.

While they share some similarities, there are also notable differences.

v Material

Composition:

Stainless

Steel: Stainless steel is an alloy primarily composed of iron, with varying

amounts of chromium, nickel, and other elements. This alloy composition gives

stainless steel its corrosion-resistant properties, making it highly durable

and suitable for outdoor and high-moisture environments.

Aluminum:

Aluminum is a non-ferrous metal known for its lightweight properties. It is

naturally resistant to corrosion due to the formation of a protective oxide

layer on its surface. However, it is not as corrosion-resistant as stainless

steel and may not be suitable for applications where exposure to harsh

environments or corrosive substances is a concern.

v Strength

and Rigidity:

Stainless

Steel: Stainless steel perforated sheets are generally stronger and more rigid

compared to aluminum perforated sheets of similar thickness. This makes

stainless steel perforated sheets suitable for applications requiring higher

strength and durability.

Aluminum:

While aluminum is lightweight, it is not as strong or rigid as stainless steel.

Aluminum perforated sheets may be preferred for applications where weight is a

concern or where a more flexible material is needed.

v Cost:

Stainless

Steel: Stainless steel perforated sheets tend to be more expensive than

aluminum perforated sheets due to the higher cost of stainless steel raw

materials and the additional processing required.

Aluminum:

Aluminum perforated sheets are generally more cost-effective compared to

stainless steel, making them a preferred choice for projects with budget

constraints.

v Appearance:

Stainless

Steel: Stainless steel has a shiny, metallic appearance that can lend a modern

and sophisticated look to applications. It is often used in architectural and

decorative applications where aesthetics are important.

Aluminum:

Aluminum has a matte finish and is available in a variety of colors and

finishes. It can provide a sleek and contemporary appearance to applications,

but it may not have the same visual impact as stainless steel.

In

summary, the choice depends on many factors such as the application

requirements, budget, desired aesthetics, and environmental conditions.

Stainless steel offers superior strength and corrosion resistance but comes at

a higher cost, while aluminum is lightweight, cost-effective, and versatile but

may not be as durable in harsh environments.

How To Select Suitable Perforated Sheets, Stainless

Steel Sheets, Aluminum Sheets or Metal Sheets?

To select

suitable perforated sheets, whether they are made of stainless steel, aluminum,

or other metals, some factors should be under consideration:

u Application

Requirements: Determine the specific requirements of your application. Consider

factors such as strength, corrosion resistance, weight, durability, and

aesthetic preferences.

u Environmental

Conditions: Assess the environmental conditions the perforated sheets will be

exposed to. For example, if the application will be outdoors or in a corrosive

environment, stainless steel may be preferred for its corrosion resistance.

Aluminum is also corrosion-resistant but may not be as suitable for highly

corrosive environments as stainless steel.

u Budget

Constraints: Consider your budget constraints. Stainless steel perforated

sheets are typically more expensive than aluminum or other metal options. If

cost is a primary concern, aluminum or other metals may be more suitable.

u Strength

and Rigidity Requirements: Evaluate the strength and rigidity requirements of

your application. Stainless steel perforated sheets are generally stronger and

more rigid compared to aluminum and other metals of similar thickness. If high

strength and rigidity are necessary, stainless steel may be the better choice.

u Weight

Considerations: Consider the weight of the perforated sheets, especially for

applications where weight is a concern, such as transportation or architectural

design. Aluminum is lightweight compared to stainless steel and may be

preferred for weight-sensitive applications.

u Aesthetic

Preferences: Determine the desired aesthetic appearance of the perforated

sheets. Stainless steel offers a shiny, metallic appearance that can lend a

modern and sophisticated look to applications. Aluminum is available in various

colors and finishes and can provide a sleek and contemporary appearance. Other

metals may offer unique aesthetic properties depending on the material and

finish.

u Customization

Options: Consider the customization options available for the perforated

sheets. Both stainless steel and aluminum perforated sheets can be customized

in terms of hole size, shape, pattern, and spacing to meet specific design

requirements.

By carefully evaluating these factors, you can select the most suitable perforated sheets, whether they are made of stainless steel, aluminum, or other metals, for your specific application. Or Consulting with a knowledgeable supplier or manufacturer can also provide valuable insights and assistance for your needs.