Commercial Kitchen Backsplash

A commercial kitchen backsplash is a protective wall covering typically installed behind cooking surfaces, such as stoves, ovens, and food preparation areas in commercial kitchens. It can protect the wall from splatters, grease, and other cooking-related messes, which makes for easier cleaning as the smooth surface. In commercial kitchen settings, hygiene and cleanliness are in highly important. Therefore, stainless steel backsplashes are often chosen for durability, stains resistance, and ease of cleaning. Besides functionality, commercial kitchen backsplashes are designed to meet health and safety regulations.

Categories

Everyone who works in a commercial kitchen has to be hardworking, and the same applies to the kitchen facilities and equipment! Heat, humidity, acid and many other things are wearing down the surfaces of various facilities, which makes stainless steel as an irreplaceable material in the commercial kitchen.

Commercial Kitchen Sink

A commercial kitchen sink is specially designed for use in commercial or professional kitchen environments. Due to various tasks, single-basin, double-basin, and three-compartment sinks can be found in commercial kitchen to meet specific demands of high-volume and intensive use typical of restaurants, catering facilities, hotels, hospitals, etc. Size and capacity of stainless steel sinks also can be designed as kitchen layouts. Besides, various installation types, including undermount, drop-in, and wall-mounted sinks, show flexibility in design. Some additional features such as drainboards, pre-rinse spray units, and integrated backsplashes, improve the efficiency in a commercial setting.

More Details

Commercial Kitchen Countertop

A commercial kitchen countertop is a work surface specially designed and constructed for use in professional kitchens, and those are found in restaurants, hotels, catering businesses, and other food service establishments. It has a high requirement about scratches and stains resistance, heat resistance, easy to clean and sanitize, therefor stainless steel countertop becomes the best choice for commercial kitchens.

More Details

Applications and Benefits of Commercial Kitchen Backsplashes

Commercial kitchen backsplashes serve several important applications in a professional kitchen setting.

Hygiene and

Sanitation:

l Preventing contamination: Backsplashes

create a barrier that helps prevent food particles, liquids, and cooling

residues from coming into contact with the walls.

l Easy cleaning: The smooth and non-porous surface of backsplash materials allow for easy cleaning and disinfection, helping to meet strict hygiene standards in commercial kitchens.

Durability and

Protection:

l Heat resistance: Backsplash materials may

need to be resistant to fire and heat, so stainless steel backsplash can

withstand high temperatures associated with cooking appliances without warping.

l Water and moisture resistance: Choosing

non-porous materials like stainless steel helps prevent water absorption,

reducing to get rust even in the presence of water.

l Stain resistance: Commercial kitchen

backsplashes are often designed to resist stains from cooking oils, sauces, and

other ingredients.

l Chemical resistance: Stainless steel commercial kitchen backsplashes are resistant to many cleaning chemicals to ensure a clean surface.

Compliance with Regulations: Health and safety regulations governing commercial kitchens is critical, which is established by health department, building department, or other relevant authorities.

Aesthetics and Design: Apart from material selection, texture and pattern, other factors can be under consideration, like well-designed lighting, incorporating logos and branding, or customized design.

Ease of Maintenance: Stainless steel backsplashes with smooth surfaces are easy to wipe clean to prevent the buildup of grease and food residues.

Customization: Customizing the backsplash design to align with brand identity of the establishment can enhance the overall branding and make the kitchen visually appealing.

Specifications

for Commercial Kitchen Backsplash

Specifications

for Commercial Kitchen Backsplash

Type: Stainless steel

sheet

Standard: GB, ASTM,

JIS, DIN

Technique: Cold

rolled

SS Grade: 201,

304, 316

Finish: Polished,

Brushed, Satin, Mirror, Embossed, etc.

Edge: Mill or Slit

Thickness: 0.8-3mm

Width: Customized

Length: Customized

Application: Residential

& Commercial Building

Packing: PVC film + waterproof paper + standard wooden package

Surface Finishes for Stainless Steel Commercial Kitchen Backsplash

Commercial kitchen backsplashes can feature various surface finishes, each contributes to different aesthetics and functional characteristics.

Polished Finish

Polished Finish

A polished finish backsplash offers a sleek and sophisticated look, creating a smooth and reflective appearance.

Satin Finish

Satin finish backsplashes combine elements of both brushed and polished finishes, provide a balanced and versatile appearance, and make resistant to scratches and fingerprints.

Brushed

Finish

Brushed finish commercial kitchen backsplashes offer a modern and industrial look, diffuse light by reducing the visibility of minor surface imperfections.

Mirror Finish

A mirror finish stainless steel backsplash creates a surface that resembles a mirror, requiring careful maintenance to preserve the mirror-like surface. Therefor do consideration while selecting mirror finish commercial kitchen backsplashes.

Pattern or

Textured finish

Embossed or textured finish backsplashes provide a unique and subtle texture, which adds visual interest and texture. And it is available in various patterns, such as diamond or linen.

FAQ (frequently asked questions)

1- What’s The Common Materials for Commercial

Kitchen Backsplashes?

Commercial kitchen

backsplashes need to meet specific requirements due to the unique demands of

the environment. The ideal material should be durable, resistant to heat and

moisture, easy to clean, and comply with health and safety regulations, such as

Stainless steel which is suitable for food preparation areas, engineered quartz

with a sleek and modern look, ceramic tiles with variety of colors and patterns

options to match the kitchen’s aesthetic, porcelain tiles for high-traffic

commercial kitchens, glass tiles which are non-porous and make them resistant

to stains, add a modern and reflective touch to the kitchen, etc.

2- Is A Backsplash Necessary in Commercial

Kitchen?

Yes, it is necessary. A backsplash

helps to prevent the accumulation of grease, food particles, and liquids on the

wall surfaces behind cooking equipment, for this purpose, it requires materials

with easy cleaning and maintenance. And it is a good protective layer for the

walls during the high-heat cooking processes, like steam and various cooking

activities. In summary, a backsplash might not be strictly mandatory, but it is

highly advisable for reasons of hygiene, sanitation, easy of cleaning, and

regulatory compliance.

3- Which Kind of Stainless Steel Finish Is

Popular For Commercial Kitchen Backsplash?

In commercial kitchens, stainless

steel is a popular choice for backsplashes due to its durability, resistance to

corrosion, and ease of cleaning. Brushed or satin finish stainless steel

backsplashes are the most common choices for commercial kitchens. The surface

has a matte appearance, with scratch & fingerprint resistance, making it

practical for a busy kitchen environment. Mirror or polished finish stainless

steel backsplashes are chosen by a highly reflective and shiny surface. Pattern

or textured finish stainless steel backsplashes not only add visual interest

but also help hide scratches and wear over time. Except that, there are

antimicrobial finish, diamond plate finish, etc. used for commercial kitchen

backsplashes.

4- How to Install Stainless Steel Backsplashes

for Commercial Kitchens?

To install a stainless steel

backsplash needs a general guide, first prepare all materials and tools

relatively, like adhesive and applicator, screws, etc. Then follow the

installation steps:

1)

Ensure

the wall surface clean, dry and smooth.

2)

Measure

the area where to be installed, and mark horizontal and vertical guidelines on

the wall.

3)

If the

backsplash panels need to be cut to fit the space, measure and mark the cutting

line on the panels. Use a jigsaw or metal shears to cut with safety glasses.

4)

Apply suitable

construction adhesive to the back side of stainless steel backsplash in even

distribution.

5)

Carefully

position the backsplash panel against the wall, and press it firmly.

6)

Secure

the stainless steel panel by screws.

7)

Clean

any excess adhesive from the surface through an appropriate cleaner. And make

double check for attached panel.

5- Is A

Protective Film Applied to Finished Surface of The Backsplash?

Yes, in many cases all panels have

a protective film applied to safeguard it during transportation, installation,

and remodeling activities. Typically, the film can be peeled off easily once

the installation is complete, revealing the finished and undamaged stainless

steel surface underneath. It’s better remove the protective film promptly after

installation to prevent any adhesive residue from becoming difficult to clean

later on.

Surface Finishes

Commercial kitchen backsplashes can feature various surface finishes, each contributes to different aesthetics and functional characteristics.

Latest Posts

Why Are More And More People Installing Stainless Steel Countertops?

If you rarely cook and the kitchen is more of a show space for you, then you may only need to focus on whether the countertops meet your aesthetic standards and overall decoration style. If you are a cooking enthusiast

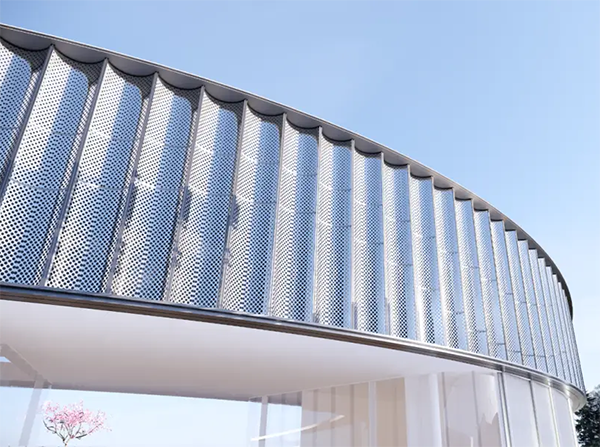

What is Perforated Sheet? How Important Does Perforated Sheet Play Role In Decor

A perforated sheet is a metal sheet that has been punctured with a series of holes in a pattern. These holes can vary in size, shape, and distribution, depending on the intended application. Perforated sheets are commonl

2024 Trend of Overall Stainless Steel Kitchen Cabinets

The latest report released by the National Kitchen and Bathroom Association (NKBA) provides a detailed overview of the cutting-edge trends in kitchen design in 2024. According to NKBA's research, the minimalist design co

Export Stainless Steel Sheets To Bangladesh

Export 201 Hot-Rolled Stainless Steel Sheets, Cold-Rolled Stainless Steel Sheets, 8K Mirror Finish Stainless Steel Sheets to Bangladesh.