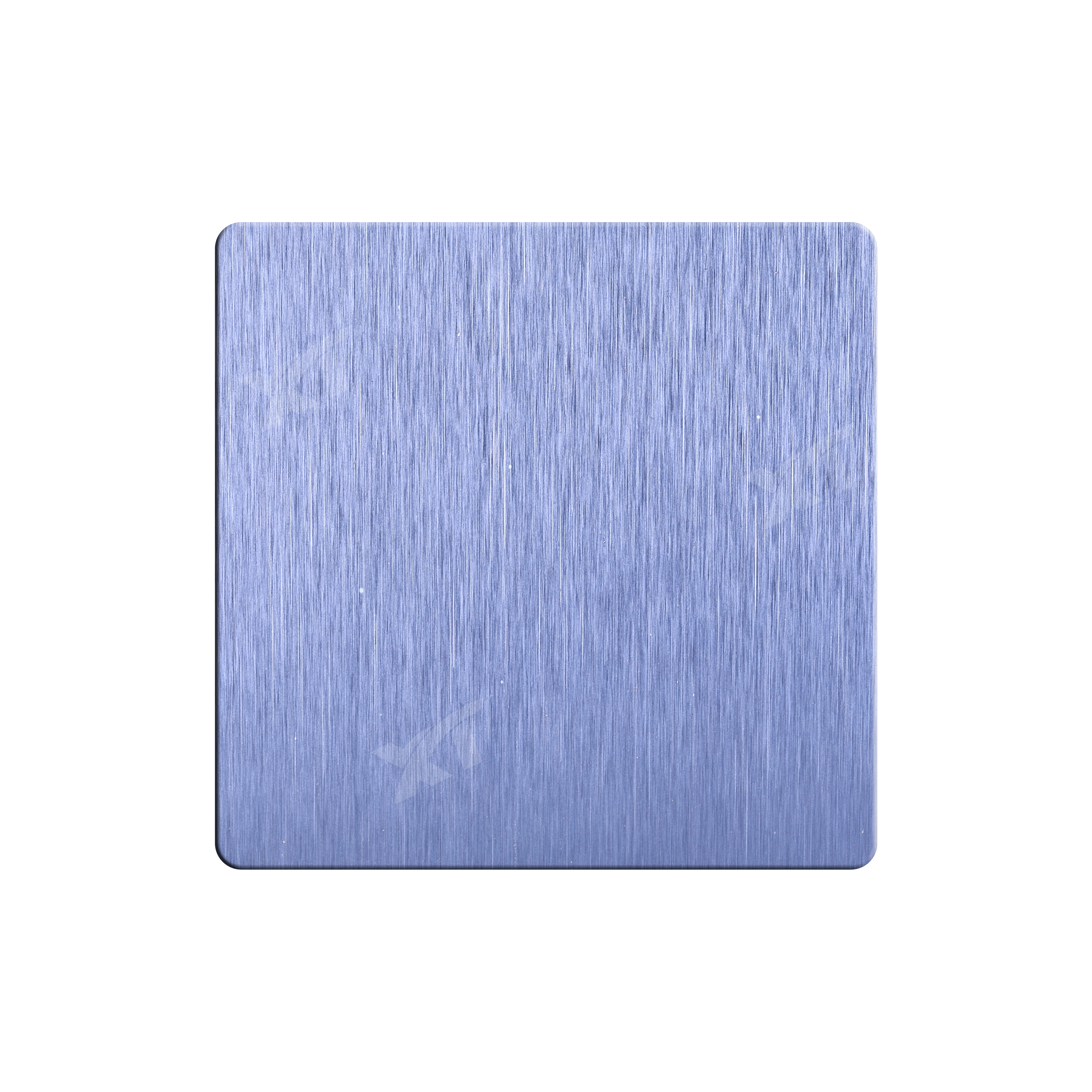

Hairline Finish Stainless Steel Sheet

Brushed finish, known as HL finish, is popular and valued not only for its aesthetic appeal but also for its durability, corrosion resistance, and ease of maintenance. The unique texture by brushing process shows a continuous lines on surface, and it can be treated with various colors, including gold, bronze, silver, black, etc. Hairline finish stainless steel sheet and panels can be found in many applications, like elevator panels, escalators, column cladding, indoor and outdoor decorations, automobile industry, signage, commercial appliance, and home appliance, etc.

Categories

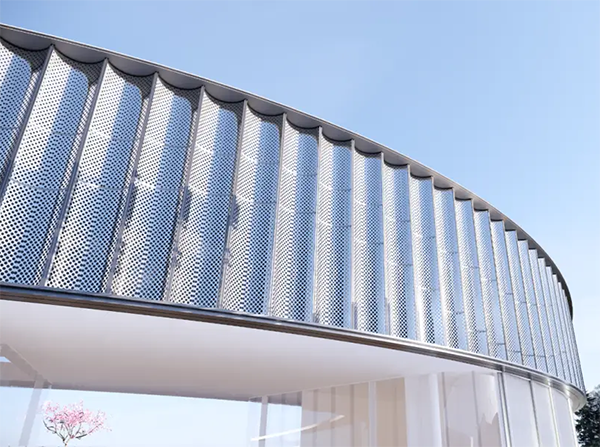

Metal wall facade cladding is exceptional in imbuing architectural projects with both structural integrity and captivating aesthetics. XTT Stainless Steel's facade cladding systems encompass a diverse array of high-quality metal options, each boasting distinct styles. These systems offer paramount protection and adornment。

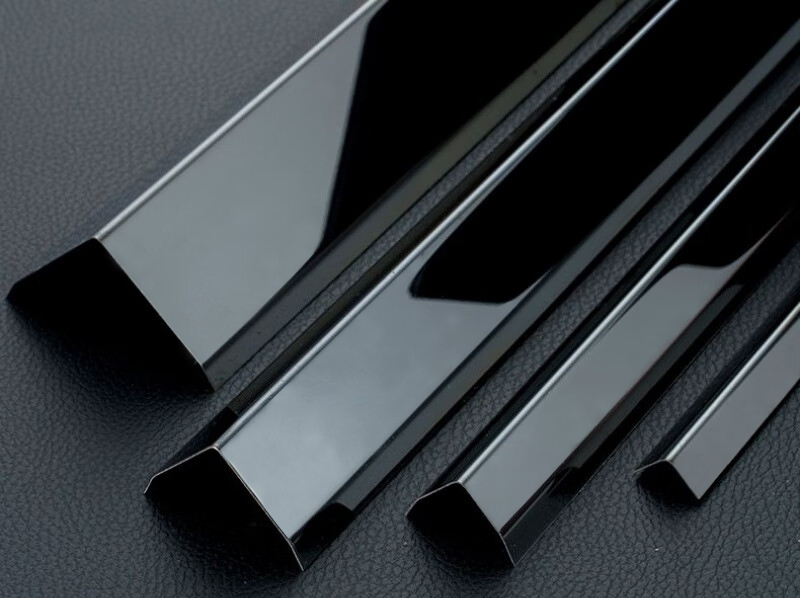

Ti-Black Finish Stainless Steel Sheet

Ti-black finish on stainless steel sheet has two different processes: water plating and electroplating. Water plating is carried out in a chemical electrolyte. Through the accumulation of anions and cations under the action of electric charges, the electrolytic ions with black color gather on the surface of the stainless steel plate, thereby forming the color of black titanium. Electroplating is to form a dense oxide film through the reduction reaction between metal ions in a vacuum plating environment, thereby forming the color of black titanium. The color of water plating is darker than that of electroplating, and the adsorption force of particles on the surface of electroplating is stronger. There is no difference in the use of the plates of the two processes, and both have good reflective effects.

More Details

PVD Finish Stainless Steel Sheet

PVD finish stainless steel sheets refer to a specialized coating onto the stainless steel surface using a vacuum coating technique, offering a range of color options, including gold, rose gold, bronze, black, and other decorative finishes. This makes PVD coated stainless steel suitable for various design applications.

More Details

Applications

for Hairline Finish Stainless Steel Sheet

Due to its uniform texture, aesthetic appeal, durability,

corrosion resistance, concealing scratches and imperfections, HL finish is

widely promoted in many applications:

Architectural Elements: Hairline finish stainless

steel is frequently used in architectural applications for building facades,

wall cladding, and interior design elements due to sleek and modern appearance.

Appliances: Many kitchen appliances,

such as ovens, rang hoods, feature hairline finish stainless steel, by

providing a stylish appearance and making surface easy to clean.

Furniture: The uniform lines

contribute to the contemporary look of stainless steel furniture. The hairline

finish is often applied to tabletops, chairs frame and other seating elements

with a touch of elegance and durability, cabinetry and storage units, bed

frames especially with a minimalist and modern design to add a refined touch to

bedroom furniture, display cabinets and showcases to add a luxurious

appearance, etc.

Elevator Interiors: The hairline finish

stainless steel is popular choice for many elements, like elevator panels,

ceiling and lighting fixtures, control panels and button plates with a

sophisticated touch and a modern appearance, kickplates and baseboards,

flooring trim due to its seamless and elegant appearance, mirror frames to add

a reflective and upscale element, column covers and sill covers, etc. The use

of hairline finish stainless steel in elevator interiors makes it well-suited

for high-traffic environments. The reflective quality of the finish can also

contribute to a sense of spaciousness with the elevator cabin.

Elevator Interiors: The hairline finish

stainless steel is popular choice for many elements, like elevator panels,

ceiling and lighting fixtures, control panels and button plates with a

sophisticated touch and a modern appearance, kickplates and baseboards,

flooring trim due to its seamless and elegant appearance, mirror frames to add

a reflective and upscale element, column covers and sill covers, etc. The use

of hairline finish stainless steel in elevator interiors makes it well-suited

for high-traffic environments. The reflective quality of the finish can also

contribute to a sense of spaciousness with the elevator cabin.

Medical Equipment: Hairline stainless steel

sheets can be used for medical equipment, such as instrument trays and carts

due to smooth and uniform surface, frames for surgical tables to add a clean

and professional appearance, medical cabinets and storage units to maintain a

sterile and hygienic environment, examination tables due to easy to sanitize,

dental equipment due to a modern and clean aesthetic, medical trolley and

carts, medical furniture and seating, etc. The use of hairline finish stainless

steel in medical equipment is driven by its ability to meet strict hygiene

standards, resist corrosion, and maintain a visually appealing and professional

environment in healthcare settings.

Signage and Branding: Brushed stainless steel

sheets are chosen for those applications, like company logos with a polished

and upscale look, building signage for exterior use to add a modern and

professional touch to the building facade, interior branding including signs

and logos in commercial environments, directional signage, retail displays,

event signage, branded wall art, informational panels, etc. The use of hairline

finish not only enhances the visual appeal but also communicates a sense of

quality and sophistication. Its corrosion resistance makes it suitable for both

indoor and outdoor applications in the realm of signage and branding.

Other Applications: Apart from that, brushed

finish stainless steel sheets can be used in lighting fixtures, retail

displays, automotive applications, consumer electronics, etc.

Specifications

for Hairline Finish Stainless Steel Sheet

Type:

Stainless steel sheet

Standard:

GB, ASTM, AISI, JIS, DIN

Technique:

Cold rolled

SS

Grade: 201, 304, 316, 430

Finish:

No.4 polishing, PVD coating

Color:

Champagne, Gold, Rose Glod, Black, Silver, etc

Edge:

Mill or Slit

Thickness:

0.3-3mm

Width:

1000mm, 1219mm, 1240mm, 1250mm, 1500mm, Customized.

Length:

Customized (Max.: 6000mm)

Application:

Elevator panels, indoor and outdoor decorations, signage, kitchenware, etc.

Packing:

PVC film + waterproof paper + standard wooden package

Material

Options for Hairline Finish Stainless Steel Sheet

304

Stainless Steel Sheet

Type

304 stainless steel sheet is easy to be fabricated through welding, bending,

and stamping due to high strength, and it can be specially used in a humidity

or high temperature situations due to waterproof and fireproof characteristics.

It is in standard specifications, making it more durable.

316

Stainless Steel Sheet

Type

316 stainless steel sheet also belongs to the 300 series of stainless sheets

except 304. It keeps same characteristics with 304 stainless steel. Due to high

corrosion resistance and versatility, it can be the first choice for marine and

coastal applications, chemical and petrochemical industries, food and beverage

industry, pharmaceutical industry, etc.

FAQ

(frequently asked questions)

1- Are There Any Special Tools for

Hairline Finish Stainless Steel?

Yes,

there are some special tools and techniques for creating a hairline finish,

such as abrasive pads or belts, belt sanders or grinders, rotary brushing

machines, surface conditioning machines by using specific finishing compounds

or polishing pastes. Apart from tools, protective masks and gear, for example,

masks, safety glasses, and gloves, are necessary to ensure the safety of the

operator. A high-quality hairline finish not only relies on proper equipment,

but also requires skillful and experienced staff.

2- Can Hairline Finish

Stainless Steel Be Used in Outdoor Signage? And How to Maintain the Signage

Made of Hairline Finish Stainless Steel?

Yes, it inherently possesses excellent

corrosion resistance, making it well-suited for outdoor environments. Proper

installation is crucial for ensuring the longevity of stainless steel sheets in

outdoor settings. To keep regular cleaning with soft cloth or sponge, wipe

along the grain rather than against it to maintain the appearance of the fine

lines. Apart from that, avoid harsh chemical to damage the surface and

compromise the finish.

3- What Kinds of Equipment or

Machines Could Be Required While Making Hairline Finish Processing?

Some specific equipment and machines are

designed for hairline finish processing, like belt sanders or grinders by

providing a consistent and controlled abrasion, rotary brushing machines to get

a uniform hairline finish on large surfaces, polishing machines to enhance the

shine and smoothness of the hairline finish, laser etching or engraving

machines to create intricate designs or patterns, dust extraction systems to

maintain a clean working environment during the abrasive processes.

4- How Many Ways Can be Done to

Get the Hairline Finish?

To

achieve a hairline finish on stainless steel, we can do it through polishing

machines automatically, or use abrasive pads manually. For cross-hatch

patterns, there are 2 fixed devices on working table to keep the workpiece

unmovable while operation, which requires labor transportation after one

direction finish, 2 times fabrication can get a cross-hairline finish in

patterns, providing a unique variation on the hairline finish.

5- Any More Processes Can be

Done After Hairline Finish on Stainless Steel Sheets?

Yes,

certainly. There are additional processes that can be performed to further

enhance the appearance, protect the surface, or impart specific properties,

such as PVD coating for color options and improvement wear resistance, laser

etching or engraving to create intricate designs, patterns, logos, or

customized decorative touch, powder coating to add extra layer of protection

against environment elements, anti-fingerprint coating beneficial for frequent

touch in high-traffic space, texturing or embossing to add depth and visual

interest, sandblasting to get a matte or textured appearance, etc.

Surface Finishes

Latest Posts

Why Are More And More People Installing Stainless Steel Countertops?

If you rarely cook and the kitchen is more of a show space for you, then you may only need to focus on whether the countertops meet your aesthetic standards and overall decoration style. If you are a cooking enthusiast

What is Perforated Sheet? How Important Does Perforated Sheet Play Role In Decor

A perforated sheet is a metal sheet that has been punctured with a series of holes in a pattern. These holes can vary in size, shape, and distribution, depending on the intended application. Perforated sheets are commonl

2024 Trend of Overall Stainless Steel Kitchen Cabinets

The latest report released by the National Kitchen and Bathroom Association (NKBA) provides a detailed overview of the cutting-edge trends in kitchen design in 2024. According to NKBA's research, the minimalist design co

Export Stainless Steel Sheets To Bangladesh

Export 201 Hot-Rolled Stainless Steel Sheets, Cold-Rolled Stainless Steel Sheets, 8K Mirror Finish Stainless Steel Sheets to Bangladesh.