Cold-Rolled Stainless Steel Strip

Cold-rolled stainless steel strips are commonly used in applications that require precision, such as the production of small components for electronics, automotive, and appliances. The smooth surface finish makes cold-rolled strips suitable for decorative applications, including trim and moldings in various industries. Cold-rolled stainless steel strips are utilized in architectural and construction applications where a polished finish and dimensional accuracy are essential. Cold-rolled stainless steel strips can be fabricated with different surface finishes, including 2B (smooth, reflective), bright annealed (mirror-like), brushed, or polished, depending on the desired appearance and application requirements.

Categories

Stainless steel strip is widely used in various industries due to its corrosion resistance, durability, and versatility. Stainless steel strips are available in different thicknesses, widths, and lengths. The dimensions are often specified in terms of gauge (thickness) and width.

Applications of Cold-Rolled Stainless Steel Strip

Cold-rolled stainless steel strips find a wide range of

applications across various industries due to their excellent properties, which

include smooth surface finish, dimensional accuracy, and enhanced strength.

Automotive Industry: Cold-rolled strips find

applications in the automotive sector for manufacturing precision components,

trim, and decorative elements. The cold-rolling process ensures tight

tolerances and a polished appearance.

Electronics and Electrical Components: These strips offer

electromagnetic interference (EMI) shielding, corrosion resistance, and

dimensional stability. Stainless steel strips are used in thermal

management applications, such as heat sinks and thermal connectors. The

material's thermal conductivity and resistance to corrosion make it suitable

for these purposes.

Precision Engineering: Industries that require

precision components, such as aerospace, medical devices, and instrumentation,

often use cold-rolled stainless steel strips. These strips offer dimensional

accuracy and smooth surfaces, making them suitable for intricate parts.

Construction and Architecture: Cold-rolled stainless steel

strips are utilized in architectural applications, construction, and interior

design for items like decorative trim, moldings, and structural components.

Decorative Applications: Cold-rolled strips are commonly

employed in decorative applications, including furniture, signage, and artistic

installations, where a smooth and polished finish is desired.

Kitchen

Appliances: The smooth and polished surface of cold-rolled stainless steel

strips makes them ideal for kitchen appliances such as refrigerator panels,

oven trims, and other decorative elements.

Consumer Goods: Various consumer goods, such as

hardware, tools, and small appliances, incorporate cold-rolled stainless steel

strips for their durability, precision, and aesthetic appeal.

When selecting stainless steel strips for electronics and

electrical components, it's essential to consider the specific requirements of

the application, including the grade of stainless steel, thickness, width,

surface finish, and any necessary post-processing treatments to ensure optimal

performance and reliability.

Specifications of Cold-Rolled Stainless Steel Strip

| Type | Stainless Steel Coil |

| Standard | ASTM, AISI, GB, JIS, DIN |

| Technique | Cold Rolled |

| SS Grade | 201, 304, 316 |

| Finish | 2B Finish, No.4 Satin Finish, No.8 Mirror Finish |

| Edge | Slit |

| Thickness | 0.22-2.5mm |

| Width | 10-600mm |

| Length | Customized |

| Application | Commercial & Residential Building |

| Packing | PVC film + waterproof paper + standard wooden package |

Latest Posts

Why Are More And More People Installing Stainless Steel Countertops?

If you rarely cook and the kitchen is more of a show space for you, then you may only need to focus on whether the countertops meet your aesthetic standards and overall decoration style. If you are a cooking enthusiast

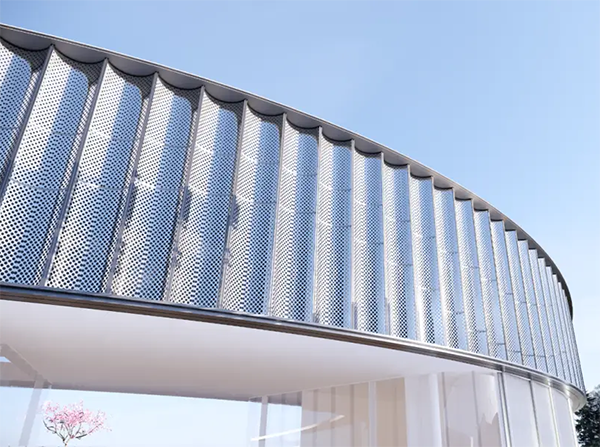

What is Perforated Sheet? How Important Does Perforated Sheet Play Role In Decor

A perforated sheet is a metal sheet that has been punctured with a series of holes in a pattern. These holes can vary in size, shape, and distribution, depending on the intended application. Perforated sheets are commonl

2024 Trend of Overall Stainless Steel Kitchen Cabinets

The latest report released by the National Kitchen and Bathroom Association (NKBA) provides a detailed overview of the cutting-edge trends in kitchen design in 2024. According to NKBA's research, the minimalist design co

Export Stainless Steel Sheets To Bangladesh

Export 201 Hot-Rolled Stainless Steel Sheets, Cold-Rolled Stainless Steel Sheets, 8K Mirror Finish Stainless Steel Sheets to Bangladesh.