Elevator Ceiling Panels

Elevator ceiling panels are parts of the interior design of the elevator and contribute to the overall aesthetics and functionality of the space. These suspended ceiling panels can be made from a variety of materials, and their design can include features such as lighting, ventilation, and emergency communication devices. Many modern elevators have integrated Led lights within the ceiling panels, which creates dynamic lighting effects.

Categories

Stainless steel plays a crucial role in elevator applications for several reasons, making it an important material for various components within an elevator system, such as elevator cab interiors, handrails, grab bars, elevator doors, frame, buttons, control panels, ceiling, exterior cladding, flooring trim, and ventilation grilles.

Elevator Wall Panels

Elevator wall panels refer to the internal surface of elevator walls. These stainless-steel wall panels are both functional and aesthetically pleasing. They provide a protective cover for the elevator cab and its’ passengers to ensure safety during transportation. From an aesthetic point of view, the elevator wall panels help to enhance the overall design and visual appeal of the elevator interior.

Elevator wall panels are made from various materials, including stainless steel, glass, wood panels, or composite materials. People choose depending on factors as design preferences, durability, and maintenance purposes. The decorative stainless steel wall panels may be designed in conjunction with overall architectural theme of the structure, especially the selection of materials, colors, and finishes for the wall panels to create a cohesive and visually pleasing environment for passengers.

More Details

Elevator Door Panels

Elevator door panels are made from different materials, depending on factors such as design preferences, durability, and safety regulations. There are various materials concerned, including stainless steel, glass, wood, laminate and composite material. But the most popular choice is stainless steel due to its durability and aesthetic appeal, and it can be used for ceiling, door panels, and wall panels.

More Details

Performance of Elevator Ceiling Panels

Elevator ceiling panels show the well performance.

u Material Durability: Ceiling panels should be made from durable materials to withstand daily wear and tear.

u Easy to Maintain: The ease of cleaning and maintenance is important for elevator ceiling panels, which improve high-efficient maintenance process.

u Fire Resistance: Elevator ceiling panels require fire-resistant materials to enhance the safety of the elevator cab in case of a fire.

u Integration with Lighting & Technology: Elevator ceiling panels may need to combinate with lighting fixtures, such as LED lighting.

u Ventilation and Airflow: Elevator ceilings may influence the airflow, so proper design should be under consideration to ensure a circulative environment for passengers.

Specifications for Elevator Ceiling Panels

| Type | Stainless steel sheet |

| Standard | GB, ASTM, JIS, DIN |

| Technique | Cold Rolled |

| SS Grade | 201, 304, 316 |

| Finish | Mirror, Matt, Brushed, Etched |

| Color | Champagne, Gold, Rose Glod, etc. |

| Edge | Mill or Slit |

| Thickness | 0.8-3mm |

| Width & Length | Customized |

| Application | Residential & Commercial Building |

| Packing | PVC film + waterproof paper + standard wooden package |

Surface Finishes of Elevator Ceiling Panels

Elevator ceiling panels can have various

surface finishes, which depends on design preferences, aesthetics, and intended

applications.

Mirror Finish

Mirror finish is known for high-gloss,

reflective appearance, adding a sense of luxury and sophistication to elevator

interior, which creates a stunning and modern look. And it can be used on both

walls and ceiling panels to create a cohesive and reflective interior.

Satin Finish

Satin finish is indeed used for elevator

ceiling designs. Scratch resistance makes it a practical choice for surfaces

that may experience some wear and tear in high-traffic areas.

Brushed Finish

Brushed finish provides a textured

appearance with a series of fine parallel lines, which helps hide minor

scratches, smudges, and fingerprints, and makes easy maintenance. Unlike highly

polished finish, brushed stainless steel ceiling panels have a subdued sheen

that reduces glare, which can be beneficial in elevator cabins because

excessive reflection could be distracting to passengers.

Etched Finish

Etched finish allows for a high degree

of customization. Elevator ceiling panels can be etched with intricate

patterns, logos, or designs, providing a unique and special look. Etched finish

can interact with lights to create subtle light and shadow effects that help

enhance the overall ambiance of the elevator cabin.

Custom Finish

Custom finish for elevator door panels

is available. Elevator ceiling panels can be customized with unique patterns,

logo integration, material combinations, color or finish matching. Custom

finish allows flexibility to enable designers to achieve specific effects and

meet the customers’ preferences.

FAQ (frequently asked questions)

1- Are There Any Options for Elevator Ceilings?

Yes, elevator ceilings can be designed by

various materials and finishes to enhance aesthetics, durability and

functionality. There are some options for elevator ceilings, such as stainless

steel ceiling, aluminum ceilings, acoustic ceilings, fabric-covered ceilings,

glass ceilings, Led ceilings, wood veneer or laminate ceilings, custom ceilings

as mirror or etched finish, etc. While selecting elevator ceiling design, it’s

essential to consider building aesthetics, maintenance requirements, safety

regulations, and budgets.

2- What Are Finishes for Elevator Ceiling Panels?

Due to the desired theme and overall

interior design, elevator ceilings can be made into various finishes, such as

brushed or polished metal, powder coating panels, wood veneer finish panels,

laminate finish panels, glass panels, textured finish ceiling panels, or Led

lighting ceiling panels.

3- How to Make the Maintenance for Stainless Steel Elevator Ceiling

Panels?

To maintain stainless steel elevator

ceilings, it involves regular cleaning, proper care, and addressing any issues

promptly to ensure longevity and aesthetic appeal.

Routine Cleaning: To clean it by using a mild detergent or a solution of warm water

and a gentle, non-abrasive cleaner. Avoid using abrasive cleaner or steel wood

to scratch the surface of stainless steel ceiling panels.

Removing Fingerprints and Smudges: Use a soft, lint-fee cloth to wipe away these marks. For stubborn

stains or fingerprints, mix vinegar with water is effective obviously.

Avoid Harsh Chemicals: Harsh chemicals, chloride-based cleaners, or products containing

bleach on stainless steel elevator ceiling panels can damage the surface.

Follow Manufacturer Guidelines: Follow any specific care and maintenance guidelines provided by

the manufacturer or the supplier of the stainless steel panels.

Regular maintenance helps preserve the

appearance of stainless steel elevator ceiling panels and ensures that they continue

to contribute to the overall aesthetics of elevator cabin.

4- What’s The Standard Packing? And Is LCL Acceptable?

The

standard packing for stainless steel panels involves measures to protect the

sheets from damage during transportation. Normally they are packed in wooden

crates or on wooden pallets, wooden pallets are commonly used for FCL (full

container load) with low cost. Each panel may be covered with a protective film

or paper to prevent scratch. After that, edge protectors are used to shield the

edges which is made of galvanized panels. Then use metal strapping or bands to

prevent movement. Labeling is required after packing, which shows stainless

steel grade, dimensions, quantity, and so on. For special requirements, the

customized packing is necessary and optional. Totally the packing process

should adhere to industry standards and regulations.

For

LCL (less container load), it is acceptable. But packing should be taken more

care to ensure without any damage during transportation. Moreover, it’s better

remind your shipping agent about the weight, because it’s easy to damage other

material if without well-protection in container. Therefore we suggest FCL if

possible.

5- Is It Possible to Use Stainless Steel Elevator Ceiling Panels for

Outdoor?

Surface Finishes

Elevator ceiling panels can have various surface finishes, which depends on design preferences, aesthetics, and intended applications.

Latest Posts

Why Are More And More People Installing Stainless Steel Countertops?

If you rarely cook and the kitchen is more of a show space for you, then you may only need to focus on whether the countertops meet your aesthetic standards and overall decoration style. If you are a cooking enthusiast

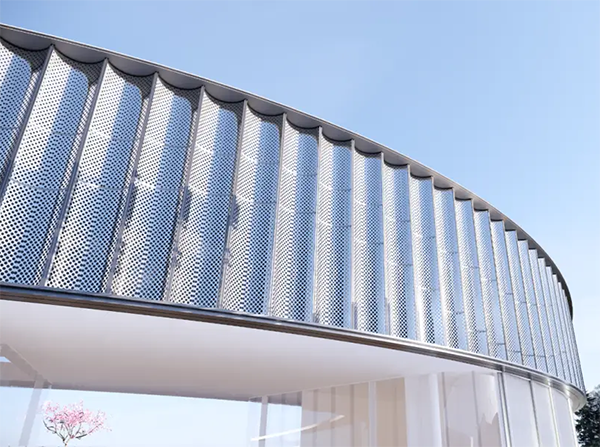

What is Perforated Sheet? How Important Does Perforated Sheet Play Role In Decor

A perforated sheet is a metal sheet that has been punctured with a series of holes in a pattern. These holes can vary in size, shape, and distribution, depending on the intended application. Perforated sheets are commonl

2024 Trend of Overall Stainless Steel Kitchen Cabinets

The latest report released by the National Kitchen and Bathroom Association (NKBA) provides a detailed overview of the cutting-edge trends in kitchen design in 2024. According to NKBA's research, the minimalist design co

Export Stainless Steel Sheets To Bangladesh

Export 201 Hot-Rolled Stainless Steel Sheets, Cold-Rolled Stainless Steel Sheets, 8K Mirror Finish Stainless Steel Sheets to Bangladesh.