Cold-Rolled Stainless Steel Coil

Cold rolling involves passing stainless steel through a series of rollers without heating it. Cold rolling refines the surface finish of the stainless steel, providing a smoother and more uniform appearance compared to hot-rolled products. Cold-rolled stainless steel coils can be produced with different surface finishes, including a bright annealed finish, a matte or dull finish, or specific patterned finishes like a 2B finish, or a mirror finish. Cold-rolled stainless steel coils are commonly used in the automotive industry, appliances, construction and architectural sectors, etc. In summary, cold-rolled stainless steel coils provide a range of advantages, including improved surface finish, dimensional precision, and enhanced mechanical properties.

Categories

Cold-rolled stainless steel coils can be produced with different surface finishes, including a bright annealed finish, a matte or dull finish, or specific patterned finishes like a 2B finish, or a mirror finish. Cold-rolled stainless steel coils are commonly used in the automotive industry, appliances, construction and architectural sectors, etc.

Mirror Finish Stainless Steel Coil

A mirror finish stainless steel coil refers to a coil of stainless steel that has undergone a specialized finishing process, resulting in a highly reflective and polished surface that closely resembles a mirror. This finish is achieved through a combination of mechanical and sometimes chemical processes to enhance the smoothness and reflectivity of the stainless steel. Mirror finish stainless steel coils are often used for high-end jewelry and decorative elements in buildings, such as wall panels, elevator doors, and trim.

More Details

Applications of Cold-Rolled Stainless Steel Coil

Cold-rolled

stainless steel coils find a wide range of applications across various

industries due to their improved surface finish, dimensional precision, and

enhanced mechanical properties

Automotive Industry:

w Automotive Trim: Cold-rolled

stainless steel coils are used for manufacturing trim components, grilles, and

decorative elements in automobiles due to their aesthetic appeal, corrosion

resistance, and formability.

w Exhaust Systems: Stainless steel

with cold-rolled finishes is often employed for manufacturing exhaust systems

in vehicles, where corrosion resistance and durability are critical.

Appliances:

w Kitchen Appliances: Cold-rolled

stainless steel is widely used in the production of kitchen appliances such as

refrigerators, ovens, dishwashers, and microwaves. The smooth finish and

corrosion resistance make it suitable for these applications.

w Washing Machines and Dryers: The durability and corrosion resistance of cold-rolled stainless

steel make it a preferred choice for the outer panels and components of washing

machines and dryers.

Construction and Architecture:

w Roofing and Cladding: Cold-rolled

stainless steel coils are used for roofing and cladding applications in the

construction industry. The material provides both durability and an attractive

appearance.

w Structural Components: Stainless steel

with cold-rolled finishes is employed for structural elements in architectural

designs, such as beams, columns, and facades.

Consumer Goods:

w Cutlery and

Utensils: Cold-rolled stainless steel is commonly used in the production

of cutlery and kitchen utensils due to its corrosion resistance, hygiene

properties, and sleek appearance.

w Furniture: The material is

utilized in the manufacturing of furniture components, including frames,

handles, and decorative elements.

Electronics and Technology:

w Electronic Enclosures: Cold-rolled

stainless steel is suitable for manufacturing enclosures and casings for

electronic devices due to its durability, corrosion resistance, and aesthetic

appeal.

w Computer Hardware: Components of

computers and other electronic devices, such as casings and brackets, may use

cold-rolled stainless steel for its combination of strength and appearance.

Medical Equipment: Cold-rolled

stainless steel is used in the production of medical furniture, such as

hospital beds, cabinets, and instrument trays, where hygiene, durability, and

corrosion resistance are crucial.

Oil and Gas Industry:

w Pipelines and Tubing: Cold-rolled stainless steel is

employed for the production of tubing and pipelines in the oil and gas

industry, where corrosion resistance and strength are essential.

Food Processing: Stainless steel with cold-rolled finishes is used for surfaces

in food processing equipment, countertops, and workstations due to its hygienic

properties and resistance to corrosion.

Chemical Processing: In the chemical industry, cold-rolled stainless steel is used for manufacturing components such as tanks, pipes, and valves due to its corrosion resistance and durability.

Specifications

of Cold-Rolled Stainless

Steel Coil

Type: Stainless Steel

Coil

Standard: ASTM,

AISI, GB, JIS, DIN

Technique: Cold

rolled

SS Grade: 201,

304, 316,

Finish: 2B Finish,

No.4 Satin Finish, No.8 Mirror Finish

Edge: Mill or Slit

Thickness:

0.22-2.5mm

Width: 1219mm,

1240mm, 1250mm, 1500mm

Application: Commercial

& Residential Building

Packing: PVC film

+ waterproof paper + standard wooden package

Latest Posts

Why Are More And More People Installing Stainless Steel Countertops?

If you rarely cook and the kitchen is more of a show space for you, then you may only need to focus on whether the countertops meet your aesthetic standards and overall decoration style. If you are a cooking enthusiast

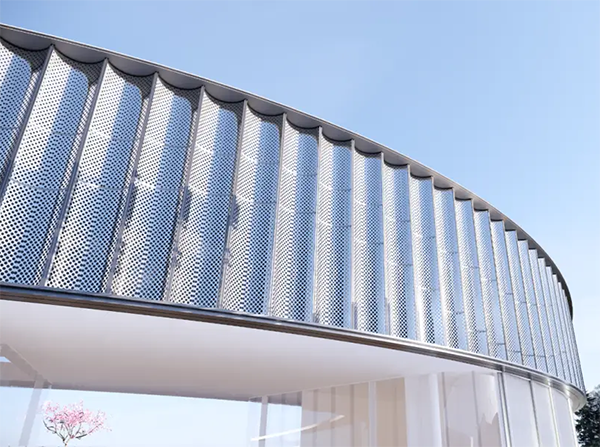

What is Perforated Sheet? How Important Does Perforated Sheet Play Role In Decor

A perforated sheet is a metal sheet that has been punctured with a series of holes in a pattern. These holes can vary in size, shape, and distribution, depending on the intended application. Perforated sheets are commonl

2024 Trend of Overall Stainless Steel Kitchen Cabinets

The latest report released by the National Kitchen and Bathroom Association (NKBA) provides a detailed overview of the cutting-edge trends in kitchen design in 2024. According to NKBA's research, the minimalist design co

Export Stainless Steel Sheets To Bangladesh

Export 201 Hot-Rolled Stainless Steel Sheets, Cold-Rolled Stainless Steel Sheets, 8K Mirror Finish Stainless Steel Sheets to Bangladesh.