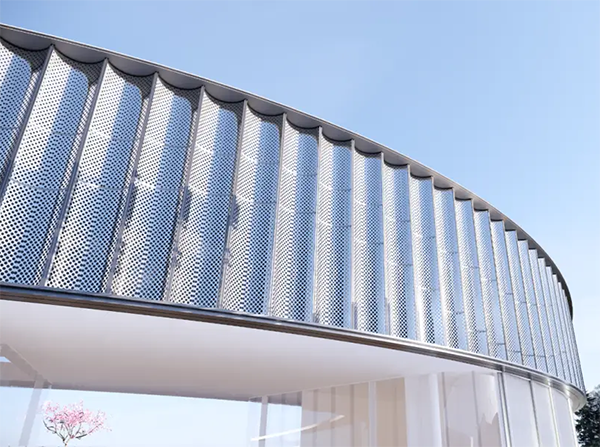

Stainless Steel Cladding

Stainless steel cladding is used in iconic structures worldwide, contributing to the architectural landscape with its blend of functionality and aesthetics due to its combination of aesthetic appeal, durability, lightweight, versatility, and corrosion resistance. Stainless steel offers a modern, sleek, and timeless appearance that complements contemporary architectural designs. The surface can be designed in various finishes as brushed, polished, or textured finishes to achieve aesthetic effects, and the cladding sheets can be easily formed and shaped to meet specific design requirements, suitable for creative and customized solutions.

Categories

As an excellent decorative material, stainless steel has strong corrosion resistance, good mechanical properties, various color and texture. It is not easy to fade, and resistant to high temperatures, which make them widely used as wall panels and ceilings during decoration, signboards and other decorations.

Decorative Stainless Steel Screen

Decorative stainless steel screens, manipulated into various shapes and designs, can be used as part of building exteriors to create visually appealing facades, and room dividers or partitions in interior spaces. You also can find them for decorative panels on walls or ceilings. Apart that, decorative screens can be integrated into furniture design to add a modern and stylish touch to the furniture. In some projects, the constructers like to use them outdoors as decorative elements for fencing or as decorative coverings for outdoor structures.

More Details

Stainless Steel Ceiling

Stainless steel is a popular choice for ceilings due to various forms to meet different designs and functional requirements. They can be fabricated into ceiling tiles, panels, planks, perforated panels, linear strips, 3D panels, custom shapes, interlocking tiles, etc. The installation is various also, it can be in a grid system, exposed grid system, or flush-mounted systems. Moreover, there are many designs, finishes and color optional, take embossed water ripple for an example, it becomes more and more popular for ceiling decoration in commercial applications, such as hotels, restaurants, company receptions, building halls, etc.

More Details

Applications of

Stainless Steel Cladding

With the desirable

properties as corrosion resistance, durability, and an attractive appearance,

stainless steel cladding finds various industries.

v Architectural Cladding: Stainless steel

cladding is widely used for covering building exteriors, facades, and wall

panels, column covers, roofing and decorative features to achieve both

functional and decorative purposes. Besides, stainless steel cladding can be

integrated with other materials, such as glass, wood, or stone, to make

visually interesting and harmonious architectural designs, and can be more

flexible in terms of shapes, patterns, and finishes.

v Architectural Cladding: Stainless steel

cladding is widely used for covering building exteriors, facades, and wall

panels, column covers, roofing and decorative features to achieve both

functional and decorative purposes. Besides, stainless steel cladding can be

integrated with other materials, such as glass, wood, or stone, to make

visually interesting and harmonious architectural designs, and can be more

flexible in terms of shapes, patterns, and finishes.

v Transportation Industry: Due to its excellent combination of

strength, corrosion resistance, and aesthetic appeal, stainless steel cladding

is used in aircraft components such as fuselage panels, wings, and other

structural elements, marine vessels for hulls, decks, and other components to

resist corrosion from saltwater exposure, railway components both exteriors and

interiors, like doors and handrails, exhaust systems for automobiles, trucks,

and motorcycles due to exposure to heat, moisture, and corrosive gases, and

other public transportation infrastructure.

v Oil and Gas Industry: stainless steel cladding can be used for

pipelines, storage tanks, heat exchangers, valves and fittings, chemical

injection systems, control panels and instrumentation in oil and gas industry. In these applications, the selection of stainless steel grade

and cladding method is crucial and depends on factors such as the specific

corrosive environment, temperature conditions, and the nature of the substances

being processed or transported.

v Food and Beverage Industry: Stainless steel

cladding is extensively used for food processing equipment, such as mixers,

conveyors, cutting machines, and grinders, storage tanks and vessels for

storing raw materials, ingredients, or finished products, stainless steel-clad

pipes and fittings to transport liquids and gases, or ovens, grills, and other

cooking equipment in the commercial kitchen. In all these applications, the use

of stainless steel cladding helps meet strict regulatory and hygiene standards

while ensuring the longevity and reliability of equipment and surfaces in the

food and beverage industry. The selection of stainless steel grades and

finishes is often tailored to specific industry requirements and the intended

use of the equipment or structures.

v Water Treatment: stainless steel cladding provides a

reliable solution for water treatment applications, such as storage tanks,

pipes and fittings, desalination plants, chemical dosing systems, water

clarifiers and filter housings, offering resistance to corrosion, ease of

maintenance, and compliance with regulatory standards.

Apart from above

applications, stainless steel cladding is applied to chemical processing,

pharmaceutical industry, power generation, medical equipment, fire Protection,

where the specific grade of stainless steel and cladding method may vary based

on the corrosive environment and the type of treatment process involved.

Specifications for

Stainless Steel Cladding

Type: Stainless steel

sheet

Type: Stainless steel

sheet

Standard: GB, ASTM,

JIS, DIN

Technique: Cold

rolled

SS Grade: 201, 304,

316L

Finish: 2B, BA, Mirror,

Brushed, Satin, hairline, Embossed, Bead Blasted.

Color: Champagne,

Gold, Rose Glod, etc.

Edge: Mill or Slit

Thickness: 0.8-3mm

Width: Customized

Length: Customized

Application: Exterior

& Interior

Packing: PVC film

+ waterproof paper + standard wooden package

Surface

Finishes of

The choice of surface finish is often influenced by the intended application, the desired appearance, and considerations such as corrosion resistance and cleanability.

No. 2B

Finish

A No. 2B finish

stainless steel cladding has a semi-matte finish with a moderate level of

reflectivity, suitable for architecture, kitchen equipment, appliances, and

decorative elements. Compared to high-end finishes, 2B finish is more economic

while still providing a quality appearance.

No. 4 Finish

No. 4 finish is

known as satin finish, achieving by using abrasives with a grit of 150-180. You

can find No.4 stainless steel cladding for wall panels, architectural features,

kitchen appliances, elevator interiors, and decorative elements in various

industries.

Bright

Annealed Finish

BA finish,

characterized by its mirror-like appearance, is suitable for applications where

cleanliness is required, such as in the food and pharmaceutical industries. Apart

that, It is commonly used in the manufacturing of kitchen appliances, such as

refrigerators, ovens, and dishwashers, where a polished and modern appearance

is desired.

Hairline Finish

A hairline finish

is commonly used in architectural cladding, such as wall panels, elevator

interiors, and decorative features, where a refined and upscale appearance is

desired, interior design like furniture, handrails, and fixtures, consumer

electronics, appliances, and gadgets, and automotive applications.

No. 8 Finish

No. 8 finish, known

as mirror finish, is the highest level of polish and reflectivity achievable on

surfaces. Mirror finish cladding is used for

wall panels, column covers, elevator interiors, and decorative features

where needs a high-end, luxurious appearance. At the same time, it tends to be

more expensive due to labor-intensive and time-consuming process.

Bead Blasted

Finish

With matte finish, Bead blasted cladding, chosen for its

unique and subdued aesthetic appeal, are used in architectural and

interior design as wall panels, facades, and column

covers, industrial settings, and various other environments. It is often

used for both functional and decorative purposes.

Embossed or

Pattern Finish

Embossed or pattern cladding offers a wide range of design options, including raised patterns (embossed), recessed patterns (debossed), and various intricate designs. The raised or recessed patterns create shadows and highlights, enhancing the overall aesthetic appeal. Normally embossed cladding is customized for unique and tailored solutions for architectural and interior design applications.

How to Apply Stainless Steel Cladding?

There

are different methods for applying stainless steel cladding, including roll

bonding, explosion bonding, or overlay welding.

Roll Bonding:

Roll Bonding:

Ø To ensure the surfaces of both the base

material and stainless steel sheets clean and free from contaminants

Ø To cut to required dimensions

Ø To place steel sheets and the base material

in contact with each other

Ø To press by rollers, creating a

metallurgical bond between the two materials

Explosion Bonding:

Ø To clean and prepare the surfaces

Ø To cut to desired shapes and sizes

Ø To stack the sheets and the base material

on top of each other

Ø To force by explosion

Overlay Welding:

Ø To clean the surfaces of the base material

thoroughly

Ø To prepare the stainless steel overlay by

cutting it to the required size

Ø To weld the stainless steel overlay onto

the base material by using appropriate welding skills (such as TIG or MIG

welding)

Ø To ensure proper bonding by controlling

parameters (heat input and welding speed)

Ø To use multiple welding passes if necessary

After cladding, inspection is necessary to ensure the bonding is uniform and meets the required quality standards.

Surface Finishes

The surface can be designed in various finishes as brushed, polished, or textured finishes to achieve aesthetic effects, and the cladding sheets can be easily formed and shaped to meet specific design requirements, suitable for creative and customized solutions.

Latest Posts

Why Are More And More People Installing Stainless Steel Countertops?

If you rarely cook and the kitchen is more of a show space for you, then you may only need to focus on whether the countertops meet your aesthetic standards and overall decoration style. If you are a cooking enthusiast

What is Perforated Sheet? How Important Does Perforated Sheet Play Role In Decor

A perforated sheet is a metal sheet that has been punctured with a series of holes in a pattern. These holes can vary in size, shape, and distribution, depending on the intended application. Perforated sheets are commonl

2024 Trend of Overall Stainless Steel Kitchen Cabinets

The latest report released by the National Kitchen and Bathroom Association (NKBA) provides a detailed overview of the cutting-edge trends in kitchen design in 2024. According to NKBA's research, the minimalist design co

Export Stainless Steel Sheets To Bangladesh

Export 201 Hot-Rolled Stainless Steel Sheets, Cold-Rolled Stainless Steel Sheets, 8K Mirror Finish Stainless Steel Sheets to Bangladesh.