Elevator Wall Panels

Elevator wall panels refer to the internal surface of elevator walls. These stainless-steel wall panels are both functional and aesthetically pleasing. They provide a protective cover for the elevator cab and its’ passengers to ensure safety during transportation. From an aesthetic point of view, the elevator wall panels help to enhance the overall design and visual appeal of the elevator interior. Elevator wall panels are made from various materials, including stainless steel, glass, wood panels, or composite materials. People choose depending on factors as design preferences, durability, and maintenance purposes. The decorative stainless steel wall panels may be designed in conjunction with overall architectural theme of the structure, especially the selection of materials, colors, and finishes for the wall panels to create a cohesive and visually pleasing environment for passengers.

Categories

Stainless steel plays a crucial role in elevator applications for several reasons, making it an important material for various components within an elevator system, such as elevator cab interiors, handrails, grab bars, elevator doors, frame, buttons, control panels, ceiling, exterior cladding, flooring trim, and ventilation grilles.

Elevator Ceiling Panels

Elevator ceiling panels are parts of the interior design of the elevator and contribute to the overall aesthetics and functionality of the space. These suspended ceiling panels can be made from a variety of materials, and their design can include features such as lighting, ventilation, and emergency communication devices. Many modern elevators have integrated Led lights within the ceiling panels, which creates dynamic lighting effects.

More Details

Elevator Door Panels

Elevator door panels are made from different materials, depending on factors such as design preferences, durability, and safety regulations. There are various materials concerned, including stainless steel, glass, wood, laminate and composite material. But the most popular choice is stainless steel due to its durability and aesthetic appeal, and it can be used for ceiling, door panels, and wall panels.

More Details

Applications and

Benefits of Elevator Wall Panels

Elevator wall panels find applications in various settings, and their benefits extend beyond just providing a protective enclosure.

Applications:

² Commercial

Buildings: Elevators in office buildings, shopping malls, and hotels often

feature aesthetically pleasing decorative wall panels to enhance the overall

interior design.

² Residential

Buildings: In high-end residential buildings or luxury homes, elevator

interiors may be designed with high-quality and visually appealing wall panels.

² Hospitals: Elevators in hospitals may use durable and easy-to-clean

stainless-steel wall panels to maintain hygiene standards.

² Public Spaces: Elevators in public spaces, such as airports or train stations,

may have robust wall panels designed to withstand heavy usage.

² Transportation: Elevators in parking structures, subway stations, or bus

terminals often use durable wall panels to withstand the wear and tear

associate with high traffic.

² Retail Environments: Elevators in retail spaces may incorporate branding elements and design features to create a cohesive atmosphere.

Benefits:

² Aesthetic Appeal: Well-designed wall panels contribute to the

overall aesthetics of a building interior, enhancing the visual appeal for

passengers or visitors.

² Customization: Decorative wall panels can be customized to match the

design ideal of the building, allowing for a cohesive and harmonious look.

² Durability: Stainless steel elevator wall panels can be durable

and scratch-resistance, and other forms of damage.

² Easy Maintenance: Mirror elevator wall panels are be easy to

clean, making maintenance and ensuring a consistently clean and attractive

appearance.

² Branding Opportunities: Elevator interior wall panels can be used

as a space for branding, displaying logos, or conveying a special message,

especially in commercial or retail buildings.

² Compliance With Safety Standards: Wall panels are designed to meet safety

standards, providing a protective barrier and ensuring the well-being of

passengers.

Specifications for

Elevator Door Panels

Specifications for

Elevator Door Panels

Type: Stainless steel

sheet

Standard: GB, ASTM,

JIS, DIN

Technique: Cold

rolled

SS Grade: 201,

304, 316

Finish: Mirror,

Matt, Brushed, etched,

Color: Champagne,

Gold, Rose Glod, etc

Edge: Mill or Slit

Thickness: 0.8-3mm

Width: Customized

Length: Customized

Application: Residential

& Commercial Building

Packing: PVC film

+ waterproof paper + standard wooden package

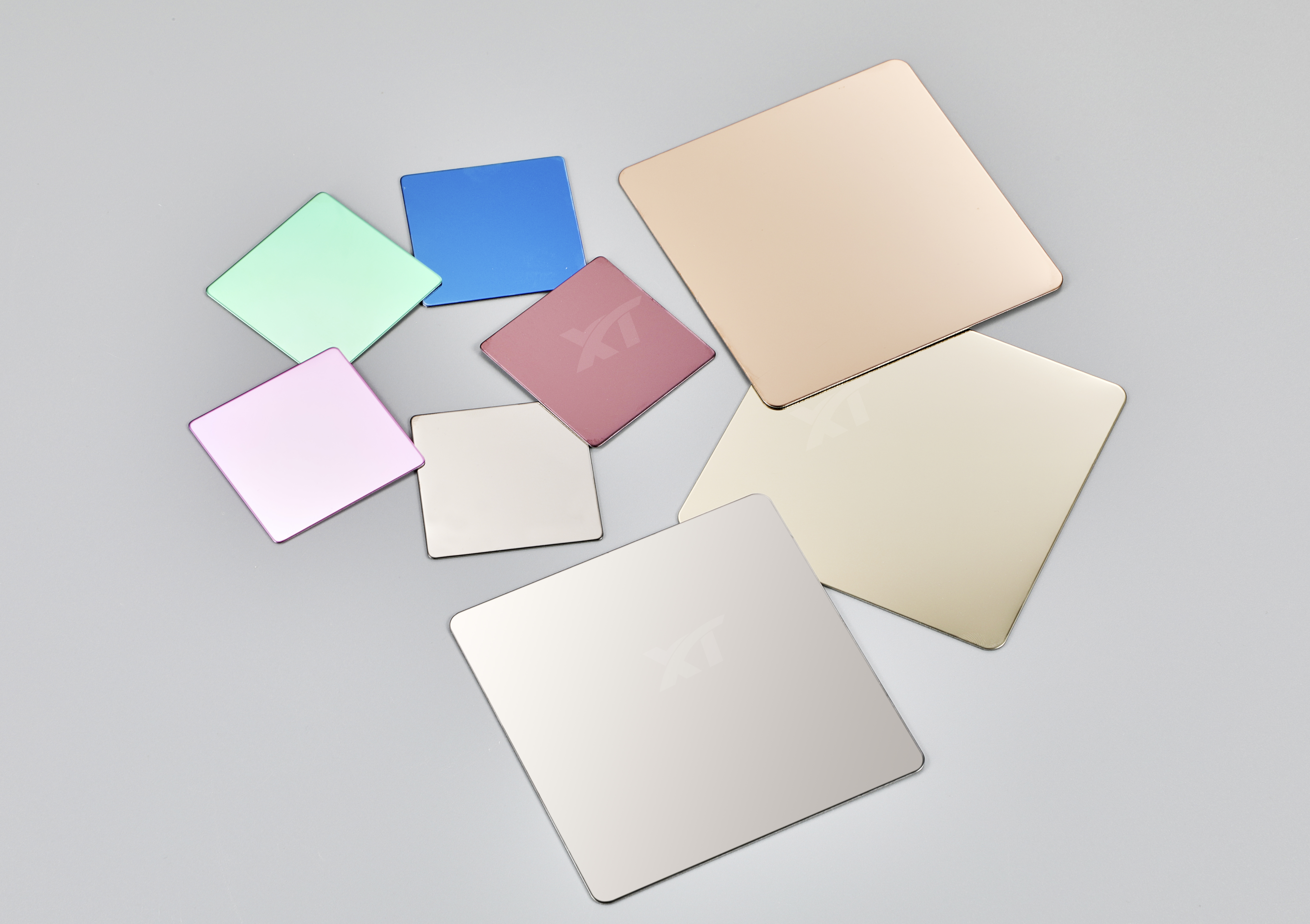

Surface

Finishes of Elevator Wall Panels

Elevator door

panels can have various surface finishes, which depends on design preferences, aesthetics,

and intended applications.

Mirror

Finish

A mirror finish on

elevator wall panels refers to a highly reflective and polished surface that

mimics the appearance of a mirror, this nature of mirror finish can give the

illusion of a large space to contribute to an open and airy feel within the

elevator cab.

Satin Finish

A satin finish is

a type of surface treatment to make a smooth, low-luster, and slightly textured

appearance on wall panels, which help minimize the visibility of fingerprints.

So it becomes a very popular choice in elevator interiors where a sleek and

modern aesthetic is desired.

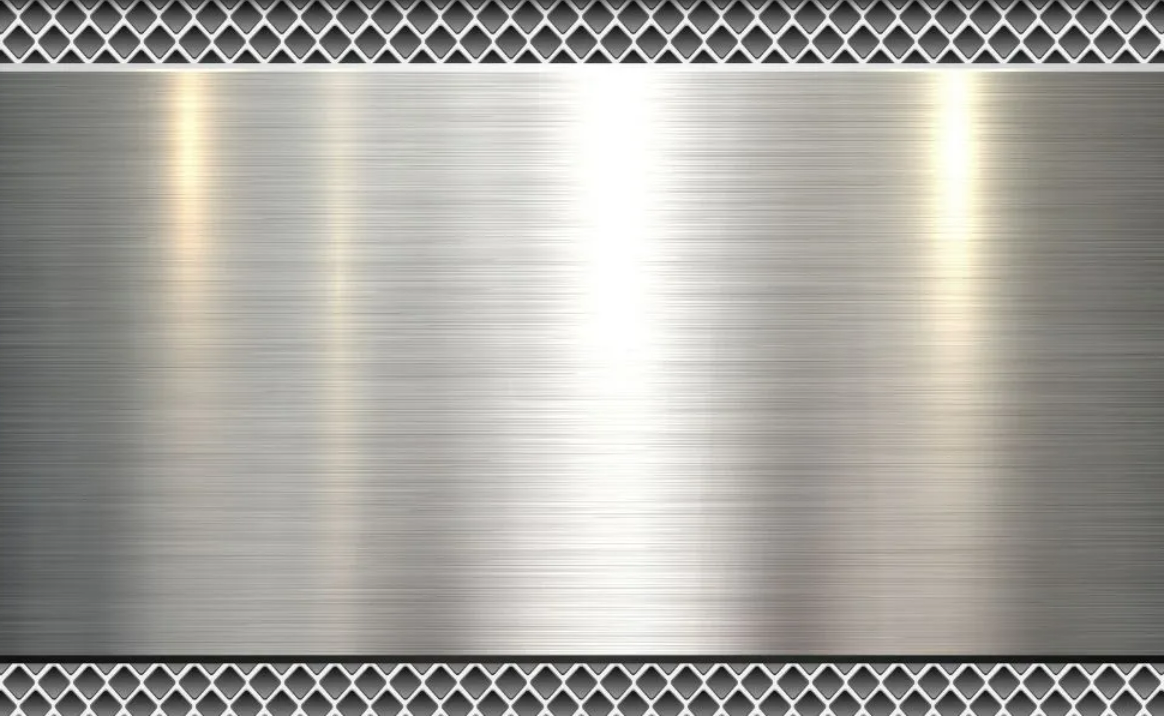

Brushed

Finish

Brushed

Finish

Brushed finish

imparts a textured surface to the material, creating a pattern of fine lines or

grooves, and it is known for its ability to hide minor scratches, scuffs, and

fingerprints, which makes it widely used in various architectural and interior

design applications, including elevator wall panel.

PVD Coated

Finish

PVD coated finish offers

a wide range of design possibilities. The process can produce different

finishes, including polished, brushed, matte, or color surfaces. Anti-fingerprint

properties conjunction with PVD coated finish can reduce the visibility of

fingerprints and smudges on the surface of Elevator wall panels.

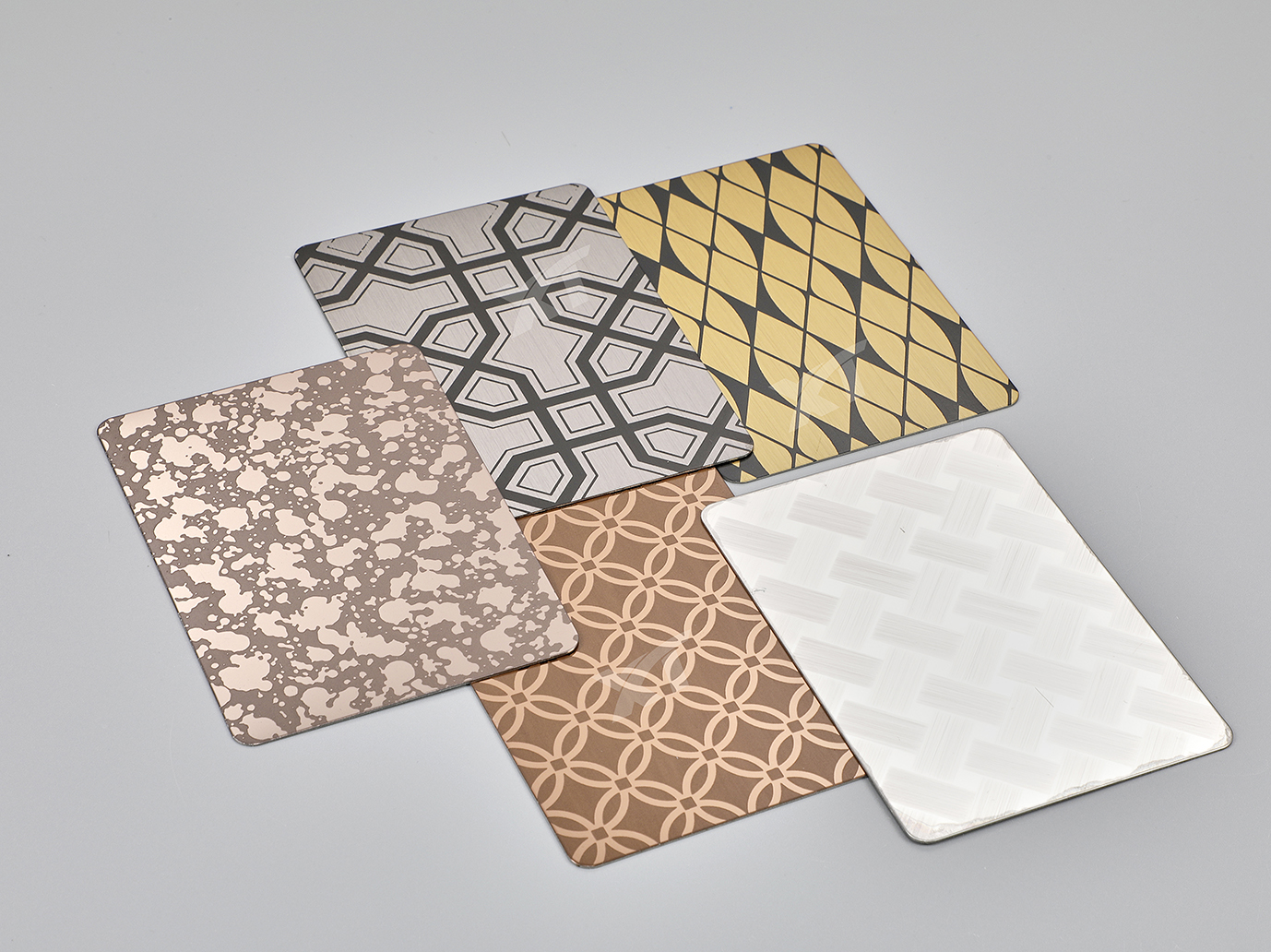

Etched Finish

An etched finish

on wall panels involves a surface treatment process that creates a decorative

pattern, design, or texture on the material. It shows fantastic decorative

appearance, privacy, brand identity, anti-glare properties, and easy

maintenance, which is a versatile design option used to enhance the aesthetic

and functional qualities of wall panels.

Embossed Finish

An embossed finish

is achieved by pressing the material between two dies, one of which has a

raised pattern, transferring the pattern onto the surface of the material,

which imparts a textured and three-dimensional appearance to the material to

create patterns or designs that enhance the visual appeal of the elevator interior.

Custom

Finish

We offer a wide

range of different finishes for elevator wall panels.

Mirror finish or

brushed finish are the most popular choice, the etched finish is also chosen as

personal taste and style.

FAQ (frequently asked questions)

1- Are elevator wall panels made of stainless

steel?

Yes, elevator wall panels are commonly made of stainless steel. Stainless steel is a popular material for elevator interiors due to its various advantageous properties: durability, hygiene, aesthetics, versatility, resistance to wear, fire resistance. While stainless steel is a common choice, elevator wall panels can also be made from other materials such as glass, wood, laminates, and other composite materials, which depends on design preferences, building theme, budget considerations, and the specific requirements of the environment where the elevator is installed.

2- Which surface finish becomes the most

popular choice for elevator wall panels?

The choice of surface finish for elevator wall panels can vary based on design preferences, architectural considerations, and the desired aesthetic of the building. Certain finishes are more commonly seen in elevator interiors, such as brushed, satin, mirror, embossed, PVD coated finish. In high-end or luxury settings, finishes convey a sense of sophistication, so mirror or PVD coated finish are more preferred. On the other hand, durability and maintenance are critical, then brushed or satin finish might be favored.

3- How to choose the size for elevator wall

panels?

The size of elevator wall panels is typically customized to fit the dimensions of the elevator cab, ensuring a seamless and precise installation. Th dimensions are influenced by the size & capacity of the elevator, the architectural design, and any specific requirements or regulations in place.

4- What is the best material for elevator wall

panels?

Several materials are used for elevator wall panels, such as stainless steel, glass, laminates, wood, stone, aluminum, and other composite materials. The best material should be the one that aligns with durability, maintenance, aesthetic preferences, budget, building regulations, which makes stainless steel as a popular choice.

5- Are

stainless steel elevator wall panels costly?

Generally stainless steel is a

little more expensive than laminates or composite materials. But stainless

steel has a higher upfront cost, its durability and resistance to corrosion and

wear can contribute to long-term cost savings. And it’s relatively easy to

clean and maintain, which is contributing to cost savings over the life of the

elevator. In summary, stainless steel elevator interior panels may be the best

choice for manufacturers.

Surface Finishes

Elevator door panels can have various surface finishes, which depends on design preferences, aesthetics, and intended applications.

Latest Posts

Why Are More And More People Installing Stainless Steel Countertops?

If you rarely cook and the kitchen is more of a show space for you, then you may only need to focus on whether the countertops meet your aesthetic standards and overall decoration style. If you are a cooking enthusiast

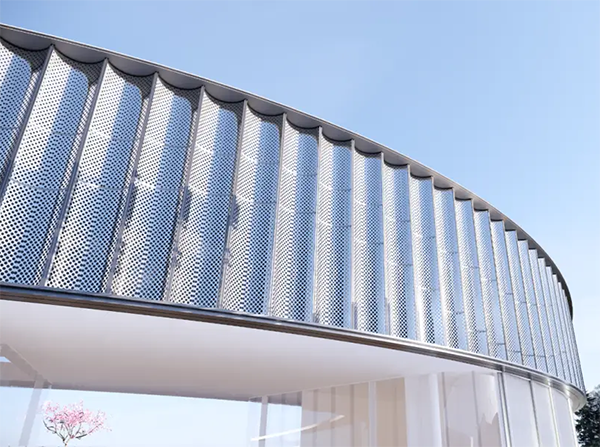

What is Perforated Sheet? How Important Does Perforated Sheet Play Role In Decor

A perforated sheet is a metal sheet that has been punctured with a series of holes in a pattern. These holes can vary in size, shape, and distribution, depending on the intended application. Perforated sheets are commonl

2024 Trend of Overall Stainless Steel Kitchen Cabinets

The latest report released by the National Kitchen and Bathroom Association (NKBA) provides a detailed overview of the cutting-edge trends in kitchen design in 2024. According to NKBA's research, the minimalist design co

Export Stainless Steel Sheets To Bangladesh

Export 201 Hot-Rolled Stainless Steel Sheets, Cold-Rolled Stainless Steel Sheets, 8K Mirror Finish Stainless Steel Sheets to Bangladesh.