Ti-Black Finish Stainless Steel Sheet

Ti-black finish on stainless steel sheet has two different processes: water plating and electroplating. Water plating is carried out in a chemical electrolyte. Through the accumulation of anions and cations under the action of electric charges, the electrolytic ions with black color gather on the surface of the stainless steel plate, thereby forming the color of black titanium. Electroplating is to form a dense oxide film through the reduction reaction between metal ions in a vacuum plating environment, thereby forming the color of black titanium. The color of water plating is darker than that of electroplating, and the adsorption force of particles on the surface of electroplating is stronger. There is no difference in the use of the plates of the two processes, and both have good reflective effects.

Categories

Metal wall facade cladding is exceptional in imbuing architectural projects with both structural integrity and captivating aesthetics. XTT Stainless Steel's facade cladding systems encompass a diverse array of high-quality metal options, each boasting distinct styles. These systems offer paramount protection and adornment。

PVD Finish Stainless Steel Sheet

PVD finish stainless steel sheets refer to a specialized coating onto the stainless steel surface using a vacuum coating technique, offering a range of color options, including gold, rose gold, bronze, black, and other decorative finishes. This makes PVD coated stainless steel suitable for various design applications.

More Details

Hairline Finish Stainless Steel Sheet

Brushed finish, known as HL finish, is popular and valued not only for its aesthetic appeal but also for its durability, corrosion resistance, and ease of maintenance. The unique texture by brushing process shows a continuous lines on surface, and it can be treated with various colors, including gold, bronze, silver, black, etc. Hairline finish stainless steel sheet and panels can be found in many applications, like elevator panels, escalators, column cladding, indoor and outdoor decorations, automobile industry, signage, commercial appliance, and home appliance, etc.

More Details

Ti-Black

Finish Stainless Steel Sheet

Ti-black

finish on stainless steel sheet has two different processes: water plating and

electroplating. Water plating is carried out in a chemical electrolyte. Through

the accumulation of anions and cations under the action of electric charges,

the electrolytic ions with black color gather on the surface of the stainless

steel sheet, thereby forming the color of black titanium. Electroplating is to

form a dense oxide film through the reduction reaction between metal ions in a

vacuum plating environment, thereby forming the color of black titanium. The

color of water plating is darker than that of electroplating, and the

adsorption force of particles on the surface of electroplating is stronger. There

is no difference in the use of the plates of the two processes, and both have

good reflective effects.

Applications

for Ti-black Finish Stainless Steel Sheet

Due to its unique appearance and material properties, the

stainless steel black titanium process has been widely used in the following

fields:

Ø Home

Decoration: Stainless steel black titanium technology can be applied to home

decoration, such as chandeliers, door handles, furniture, etc., to create a

modern and simple sense of space.

Ø Architectural Decoration: In architectural decoration, stainless steel black titanium

technology has also been widely used, such as stair handrails, wall decorative

panels, etc., which increases the beauty and texture of the space.

Ø Automotive

Industry: Stainless steel black titanium technology can also be used in the

automotive industry, such as steering wheels, front fascias, door handles and

other components, which enhances the high-end feel and texture of the car.

Ø Electronic

Devices: Manufacturers of electronic devices, such as smartphones, laptops, and

other gadgets, may use titanium black stainless steel for casings and

components to achieve a sleek and stylish appearance.

Ø Jewelry and

Accessories: Titanium black finish is also popular in the jewelry industry,

providing an alternative to traditional metals. It is often used in the

production of rings, bracelets, watches, and other accessories.

Specifications of Ti-Black Finish Stainless Steel Sheet

Type:

Stainless steel sheet

Type:

Stainless steel sheet

Standard:

GB, ASTM, AISI, JIS, DIN

Technique:

Cold rolled

SS

Grade: 201, 304, 316, 430

Edge:

Mill or Slit

Thickness:

0.3-3mm

Width:

1000mm, 1219mm, 1240mm, 1250mm, 1500mm, Customized.

Length: Customized (Max.: 6000mm)

Finish: Brushed, Mirror, Sandblasted, ect.

Application:

Home Decoration, Architectural

Decoration, Automotive Industry etc.

Packing:

PVC film + waterproof paper + standard wooden package

Will

Black Titanium Stainless Steel Fade?

During the use of stainless

steel, corrosion protection is generally achieved through surface oxide films.

Black titanium stainless steel is a kind of stainless steel that has undergone

special surface treatment. Its surface hardness is greatly improved and its

corrosion resistance is also stronger. The titanium and other metal elements

added to black titanium stainless steel can produce a denser and smoother

surface film, which is more difficult to be corroded in corrosive environments.

The corrosion resistance of black titanium stainless steel is more than 10

times higher than that of ordinary stainless steel.

The surface of black titanium stainless steel is sprayed with a layer of black oxide surface. This surface treatment becomes the outermost protective layer of the steel parts, providing secondary protection to the steel parts, thus preventing the surface of the steel parts from easily rusting and corroding. In addition, a variety of metal elements are added to black titanium stainless steel during the production process, which stabilizes its chemical properties, improves the quality of steel production, makes black titanium steel less likely to fade, and expands its usable range and application fields.

Advantages of Ti-Black Stainless Steel Sheet

Compared with traditional

precious metals such as copper and gold, Ti-black Stainless Steel Sheet process

has the following advantages:

² High Hardness: The black

titanium stainless steel process undergoes high-temperature oxidation treatment

and other processes to form a dense oxide film on the surface, which can

improve its hardness and wear resistance.

² Anti-Corrosion: Stainless

steel itself has anti-rust properties, and the oxide film of black titanium

metal makes it less susceptible to external corrosion.

² Aesthetic Appeal: The black

metal made of stainless steel and black titanium has a deep and noble color and

is suitable for modern decoration styles.

To sum up, the stainless

steel black titanium process is a material processing technology that is both

aesthetic and practical, and has been widely used in home furnishings,

construction, automobiles and other fields. With the development of technology,

stainless steel black titanium technology will have broader application

prospects.

Latest Posts

Why Are More And More People Installing Stainless Steel Countertops?

If you rarely cook and the kitchen is more of a show space for you, then you may only need to focus on whether the countertops meet your aesthetic standards and overall decoration style. If you are a cooking enthusiast

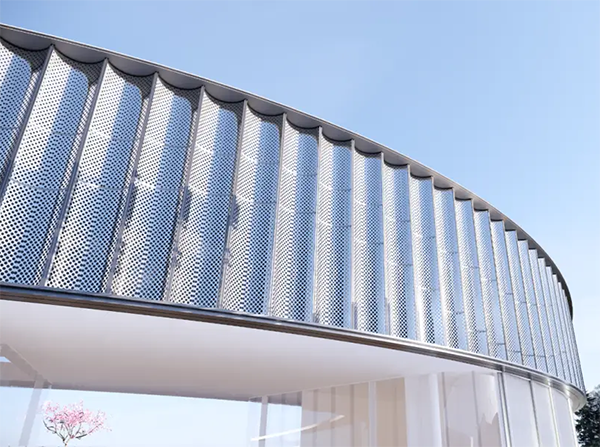

What is Perforated Sheet? How Important Does Perforated Sheet Play Role In Decor

A perforated sheet is a metal sheet that has been punctured with a series of holes in a pattern. These holes can vary in size, shape, and distribution, depending on the intended application. Perforated sheets are commonl

2024 Trend of Overall Stainless Steel Kitchen Cabinets

The latest report released by the National Kitchen and Bathroom Association (NKBA) provides a detailed overview of the cutting-edge trends in kitchen design in 2024. According to NKBA's research, the minimalist design co

Export Stainless Steel Sheets To Bangladesh

Export 201 Hot-Rolled Stainless Steel Sheets, Cold-Rolled Stainless Steel Sheets, 8K Mirror Finish Stainless Steel Sheets to Bangladesh.