Elevator Door Panels

Elevator door panels are made from different materials, depending on factors such as design preferences, durability, and safety regulations. There are various materials concerned, including stainless steel, glass, wood, laminate and composite material. But the most popular choice is stainless steel due to its durability and aesthetic appeal, and it can be used for ceiling, door panels, and wall panels.

Categories

Stainless steel plays a crucial role in elevator applications for several reasons, making it an important material for various components within an elevator system, such as elevator cab interiors, handrails, grab bars, elevator doors, frame, buttons, control panels, ceiling, exterior cladding, flooring trim, and ventilation grilles.

Elevator Ceiling Panels

Elevator ceiling panels are parts of the interior design of the elevator and contribute to the overall aesthetics and functionality of the space. These suspended ceiling panels can be made from a variety of materials, and their design can include features such as lighting, ventilation, and emergency communication devices. Many modern elevators have integrated Led lights within the ceiling panels, which creates dynamic lighting effects.

More Details

Elevator Wall Panels

Elevator wall panels refer to the internal surface of elevator walls. These stainless-steel wall panels are both functional and aesthetically pleasing. They provide a protective cover for the elevator cab and its’ passengers to ensure safety during transportation. From an aesthetic point of view, the elevator wall panels help to enhance the overall design and visual appeal of the elevator interior.

Elevator wall panels are made from various materials, including stainless steel, glass, wood panels, or composite materials. People choose depending on factors as design preferences, durability, and maintenance purposes. The decorative stainless steel wall panels may be designed in conjunction with overall architectural theme of the structure, especially the selection of materials, colors, and finishes for the wall panels to create a cohesive and visually pleasing environment for passengers.

More Details

Applications and

Benefits of Elevator Door panels

Stainless steel Elevator Door Panels are indeed a versatile

material that offers a combination of durability, aesthetics, and hygiene,

making it suitable for a wide range of environments:

Commercial Buildings:

Commercial Buildings:

※ Applications: Office

buildings, hotels, shopping malls, or other public areas.

※ Benefits:

Robust design suitable for high-traffic areas

A sophisticated and modern aesthetic

Corrosion resistance to ensure longevity

Easy maintenance and clean.

Residential Buildings:

※ Applications: Apartments,

condos, penthouses, villas.

※ Benefits:

Contribute to a luxurious atmosphere with elevates aesthetics.

Compatible with modern and simple design themes.

Maintain a high-quality appearance due to durability and

resistance to damage.

Easy for cleaning, makes it suitable for residential maintenance.

Hospitals & Healthcare Facilities

※ Applications: Hospitals,

clinics, medical facilities.

※ Benefits:

Stains and bacteria resistance suitable for a sterile

environment.

Suitable for specific places like operation rooms due to

durability.

Easy to clean and maintenance.

Government Buildings:

※ Applications: Government

offices, courts, public spaces.

※ Benefits:

Elegance and professional appeal.

Simple maintenance required.

Transportation Hubs:

※ Applications:

Subway, train stations, airports.

※ Benefits:

Resilience in

high-traffic environments.

Modern aesthetic

for public spaces.

Resistance to wear

and corrosion.

Educational Institutions:

※ Applications:

Universities, schools, educational Institutions.

※ Benefits:

Modern and

aesthetic suitable for educational environments.

Durability

suitable for daily use by students and staff.

Compatibility with

various architectural designs.

Industrial Facilities:

※ Applications: Industrial

facilities, factories, plants.

※ Benefits:

Strength and

durability for heavy industrial use.

Corrosion resistance suitable for hard environments.

Specifications for

Elevator Door Panels

Type: Stainless steel

sheet

Type: Stainless steel

sheet

Standard: GB, ASTM,

JIS, DIN

Technique: Cold

rolled

SS Grade: 201,

304, 316

Finish: Mirror,

Matt, Brushed, etched,

Color: Champagne,

Gold, Rose Glod, etc

Edge: Mill or Slit

Thickness: 0.8-3mm

Width: Customized

Length: Customized

Application: Residential

& Commercial Building

Packing: PVC film

+ waterproof paper + standard wooden package

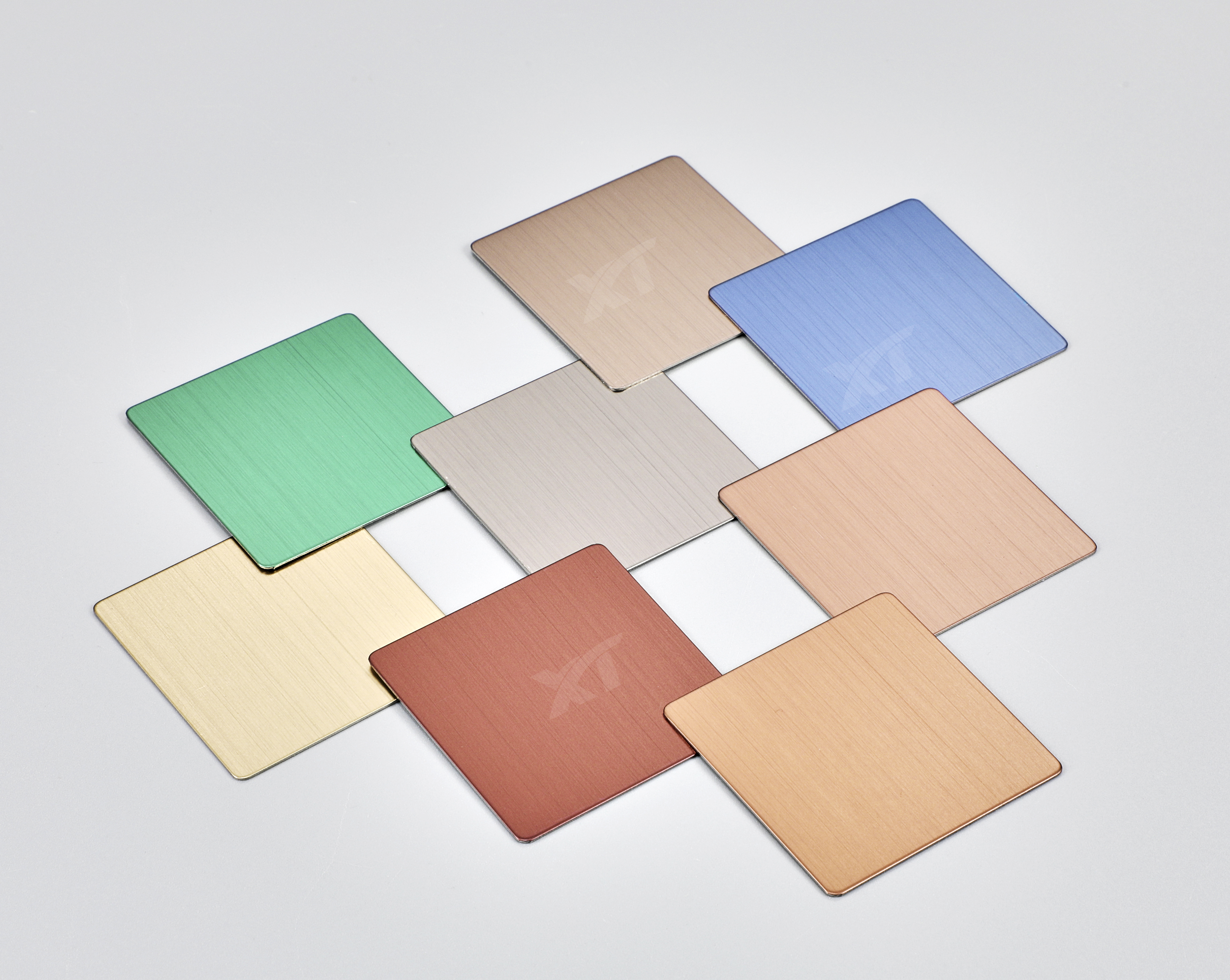

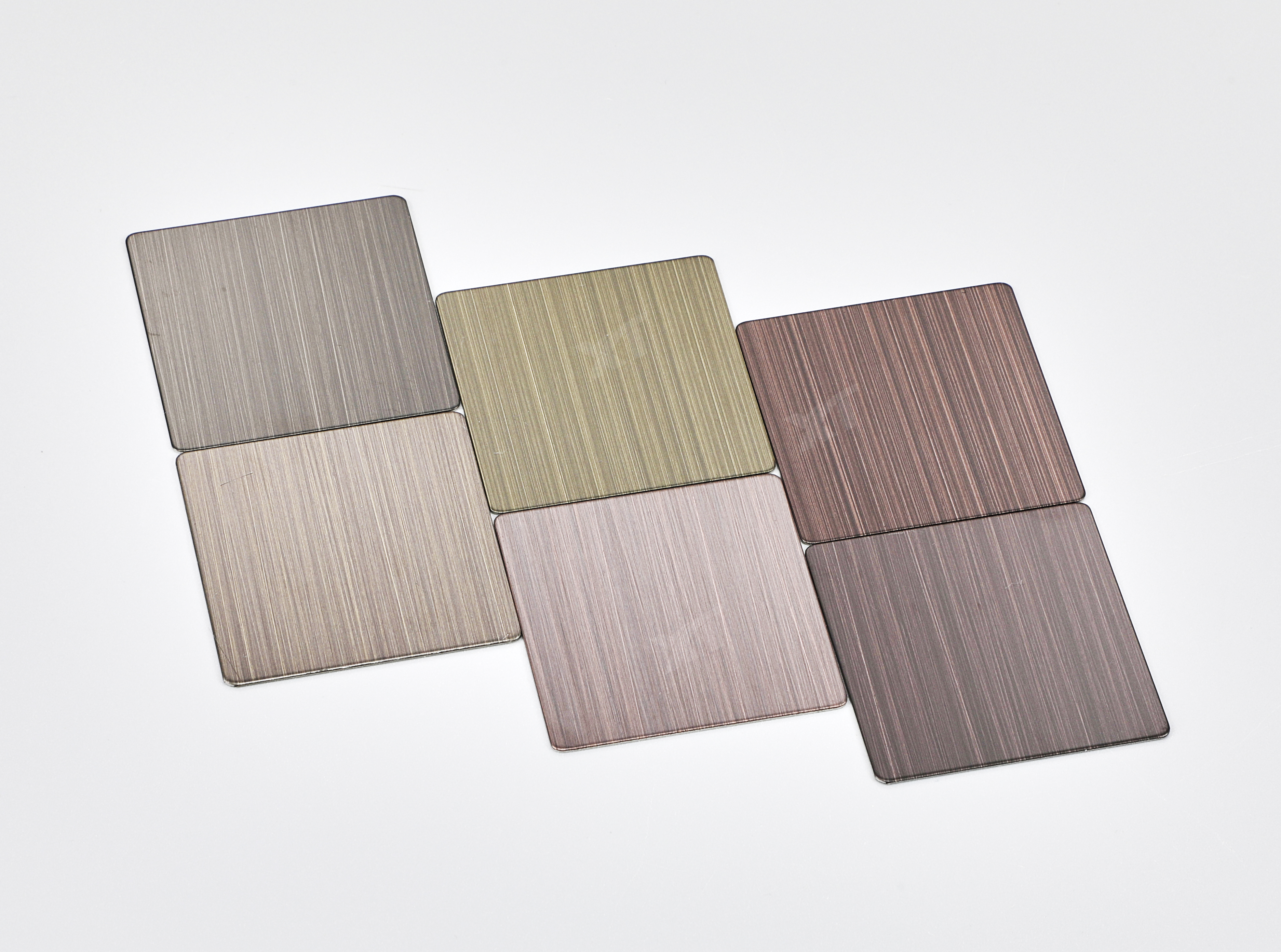

Surface

Finishes for Elevator Door Panels

Elevator door panels can have various surface finishes, which depends on design preferences, aesthetics, and intended applications.

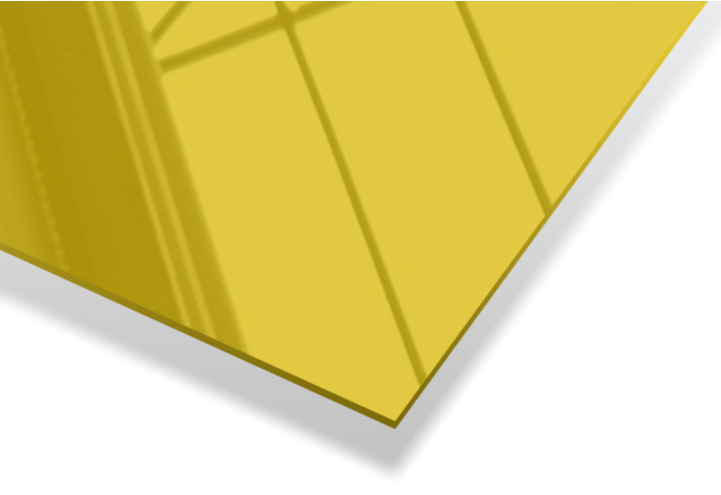

Mirror

Finish

Mirror

Finish

Mirror finish is one common process of stainless steel elevator door panels. It is simply to polish the surface through either physical or chemical polishing. Polishing grades are various, such as 6K, 8K, 10K. Mirror finish is contributed simple and fashionable aesthetics.

Satin Finish

Satin Finish

Satin finish is a special sanding treatment, forming a unique texture, which can increase the slip resistance of sheet, suitable for decoration in public places such as steps, corridors, balconies and stairs. It is a popular choice for decorative boards.

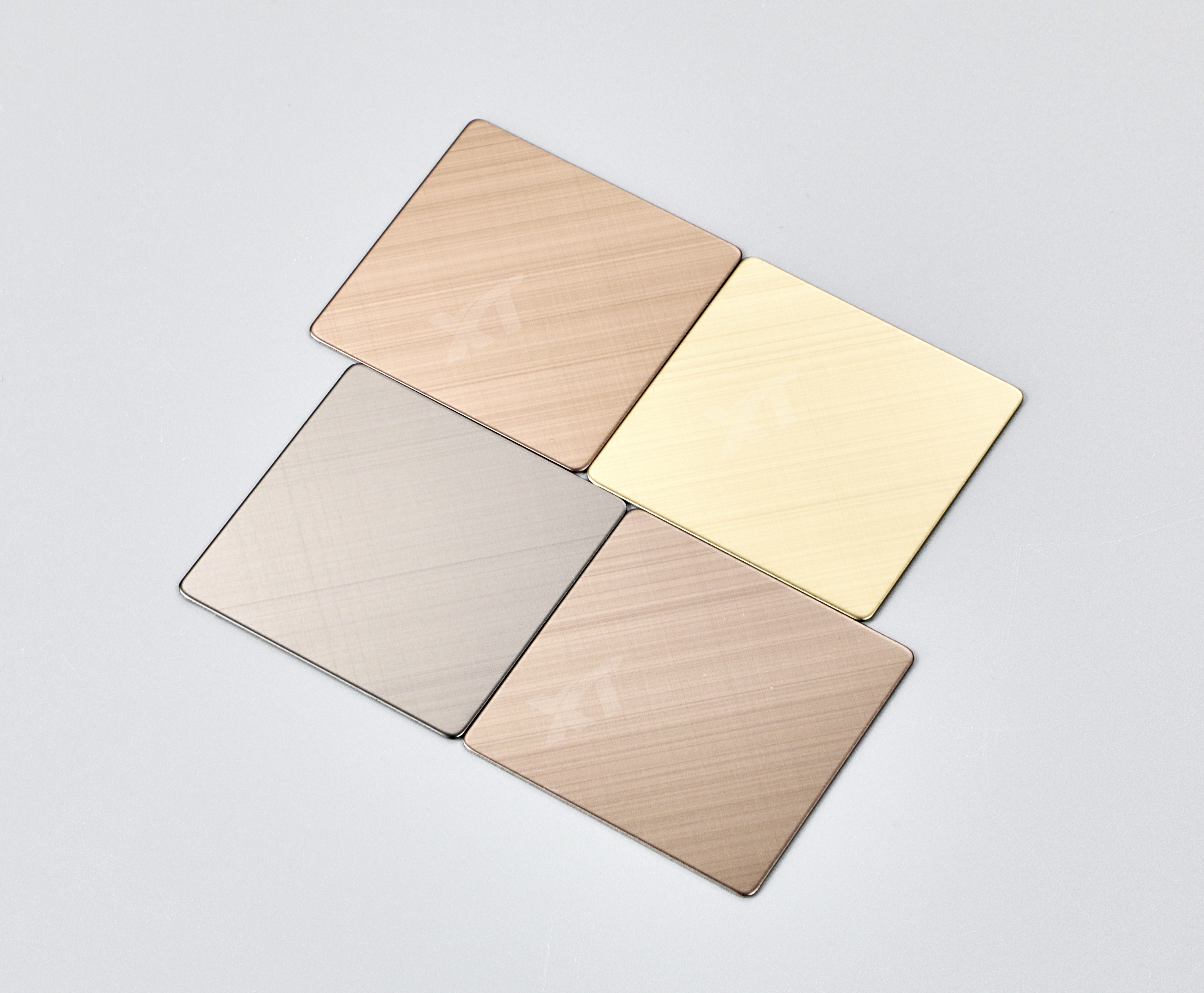

Brushed

Finish

With the strong wear resistance and fine luster characteristics, brushed finish is widely used in electronic equipment, household appliances, mechanical equipment and so on.

PVD Coated

Finish

PVD coated finish is conjunction with mirror finish or sandblasting finish to improve the surface performance of stainless-steel elevator door panels. PVD coated finish is widely used in household appliance industry, automobile industry.

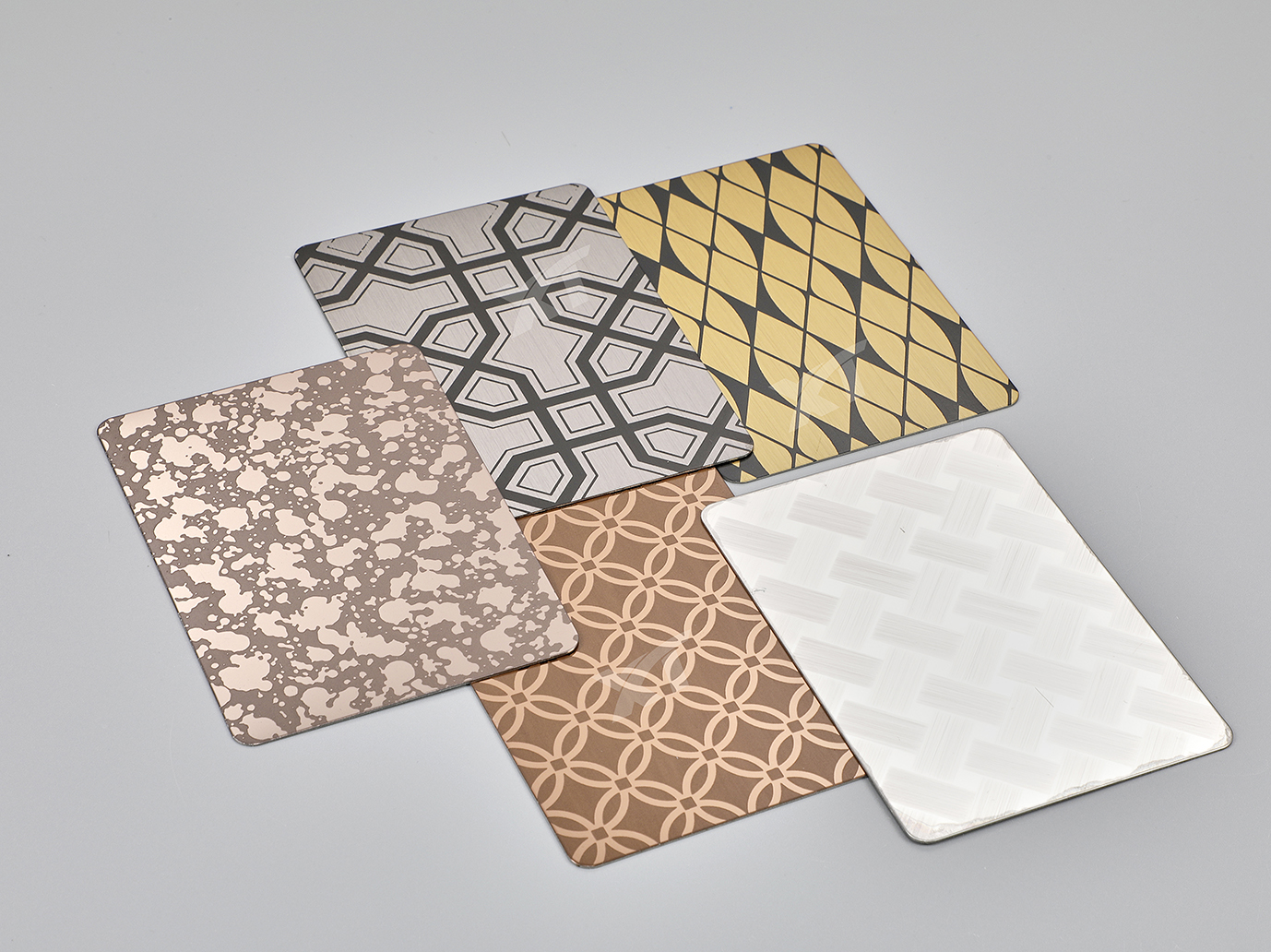

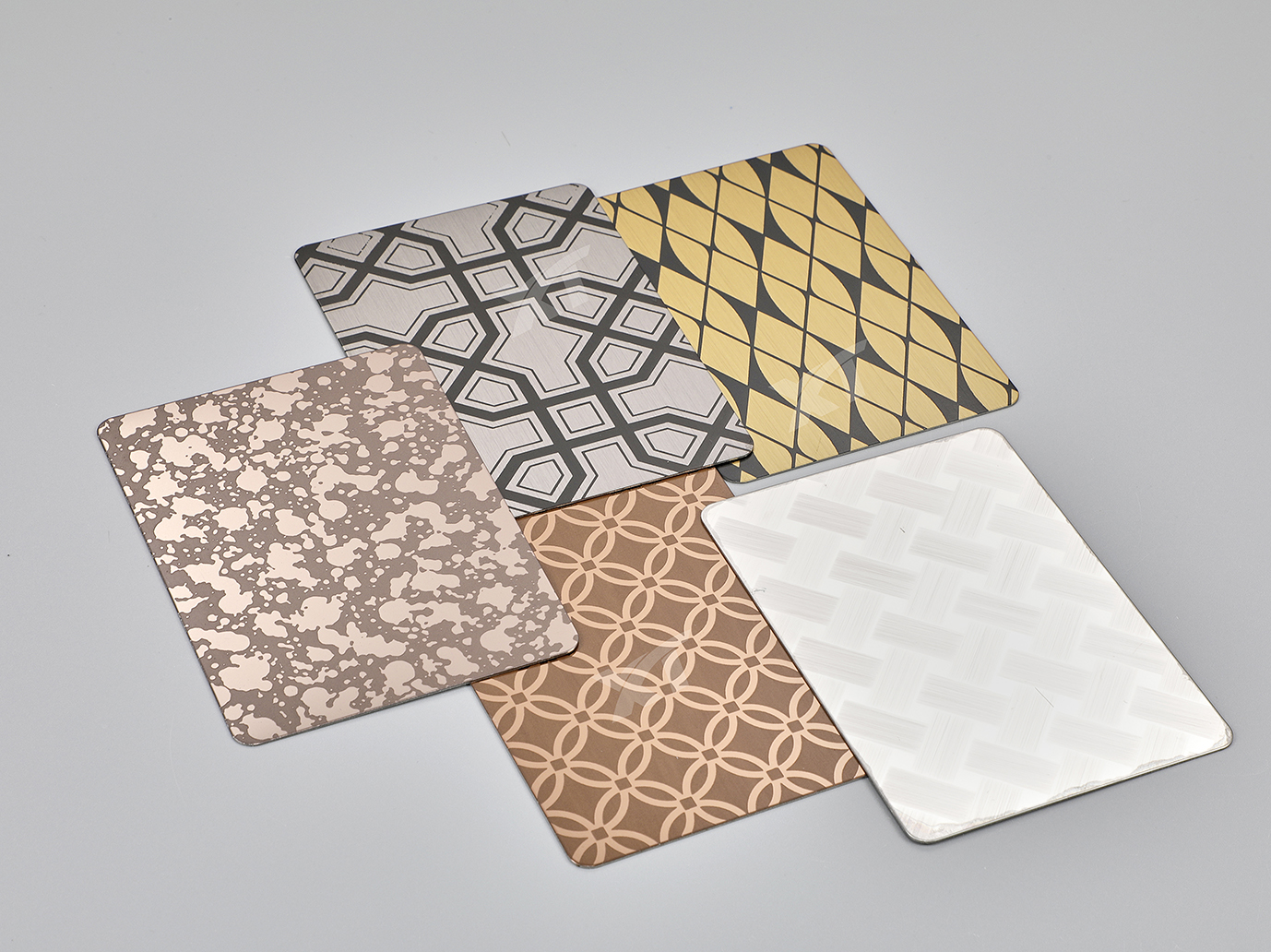

Etched Finish

Etched Finish

With high wear-resistance and anti-scratching, etched finish stainless steel sheet is widely use in hotels, entertainment places, high-end stores, wall cladding panels, ceilings, signboards, elevator doors, etc.

Custom

Finish

Custom finish for

elevator door panels is available.

FAQ (frequently

asked questions)

1- What’s the common materials for elevator

door panels?

Common materials used for elevator

door panels include:

1)

Stainless

steel: It is one of the most popular choice because of its durability,

corrosion resistance, and modern aesthetic,

2)

Glass:

glass panels are used for a more contemporary and elegant appearance. They can be

widely used in conjunction with other materials like stainless steel or

aluminum.

3)

Aluminum:

It is in lightweight, corrosion resistance, and can be crafted in various

processes, so it is often used to achieve different looks.

4)

Laminate:

Laminate material can provide a big range, such as colors, wood grains,

patterns, which make them lots of choices for elevator panels. And they are

also easy to clean and maintain.

Apart from above mentioned

materials, there are some other materials like wood, plastic laminates,

composite materials. All the choice of material may depend on factors such as

design theme of whole building, safety regulations, etc.

2- How to select a door panel for elevator?

We have to consider many factors

while selecting door panels for elevator, first of all, safety and compliance

are considered as most important, then we need to consider the durability of

material, especially for heavy use, after that design is also important, door

panel material should be matching with the design theme of the building. Apart

from above factors, there are some others, like environmental consideration,

climate, functionality, budget, building type and purpose, etc. Ultimately, the

selection of elevator door panels involves finding a balance.

3- What’s the thickness of stainless-steel

elevator door panel?

The thickness may depend on the

gauge. Normally the thickness of stainless-steel elevator door panel is in the

range of 16 to 18 gauge. For 16 gauge, it requires a thicker stainless steel

door panel to provide more durability and strength. For 18 gauge, it is a

common thickness for stainless steel door panels.

4- How to do the maintenance for stainless

steel elevator door panels?

Here are some tips to maintain

stainless-steel elevator door panels:

1)

To

wipe with a soft, clean cloth or sponge for regular cleaning. Use a mild

detergent or a stainless-steel cleaner to remove dirt, fingerprints, etc.

2)

Do not

use abrasive pads, steel wool, or rough brushes, as they can scratch the

surface.

3)

To

choose a suitable cleaner or a mixture of mild soap with water.

4)

Periodically

polish the stainless steel door panels.

5)

Inspect

regularly for any signs of corrosion. If corrosion is detected, address it

promptly by cleaning the affected area and applying a polish or protective

coating.

Regular maintenance not only keeps

the door panels looking good but also helps prevent long-term damage and extend

the lifespan.

5- How to assemble elevator door panels? And

what should be paid attention?

While assembling elevator door

panels, some key factors should be under considerations: First step, follow the

manufacturer installation instructions and guidelines for the specific elevator

door panels. Second step, ensure accurate measurements for all components to guarantee

proper fit and alignment. Third step, after proper alignment, test the movement

of the elevator doors to ensure smooth operation, then make fastening with

screws and bolts. Fourth step, make the electrical connections, ensure that all

wiring and connections are secure and properly insulated. Follow electrical

safety guide to prevent short circuits. At last, Seal the test, while sealing, we

have to do it properly to prevent air leaks and contributes to energy

efficiency. Test and verify all safety features of elevator door system to

ensure it runs properly.

After install all processes,

ensure that the individuals should be trained and certified for the specific

tasks.

Surface Finishes

Elevator door panels can have various surface finishes, which depends on design preferences, aesthetics, and intended applications.

Latest Posts

Why Are More And More People Installing Stainless Steel Countertops?

If you rarely cook and the kitchen is more of a show space for you, then you may only need to focus on whether the countertops meet your aesthetic standards and overall decoration style. If you are a cooking enthusiast

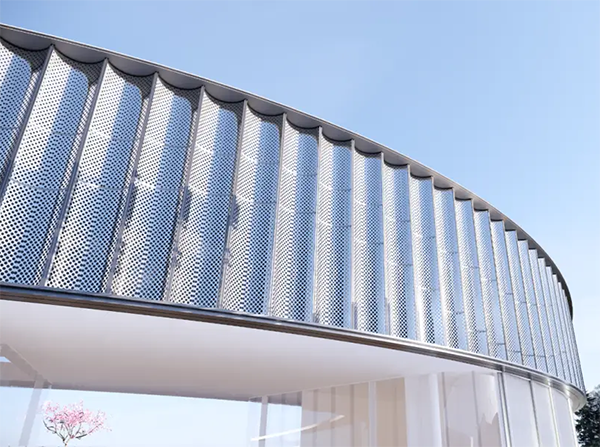

What is Perforated Sheet? How Important Does Perforated Sheet Play Role In Decor

A perforated sheet is a metal sheet that has been punctured with a series of holes in a pattern. These holes can vary in size, shape, and distribution, depending on the intended application. Perforated sheets are commonl

2024 Trend of Overall Stainless Steel Kitchen Cabinets

The latest report released by the National Kitchen and Bathroom Association (NKBA) provides a detailed overview of the cutting-edge trends in kitchen design in 2024. According to NKBA's research, the minimalist design co

Export Stainless Steel Sheets To Bangladesh

Export 201 Hot-Rolled Stainless Steel Sheets, Cold-Rolled Stainless Steel Sheets, 8K Mirror Finish Stainless Steel Sheets to Bangladesh.