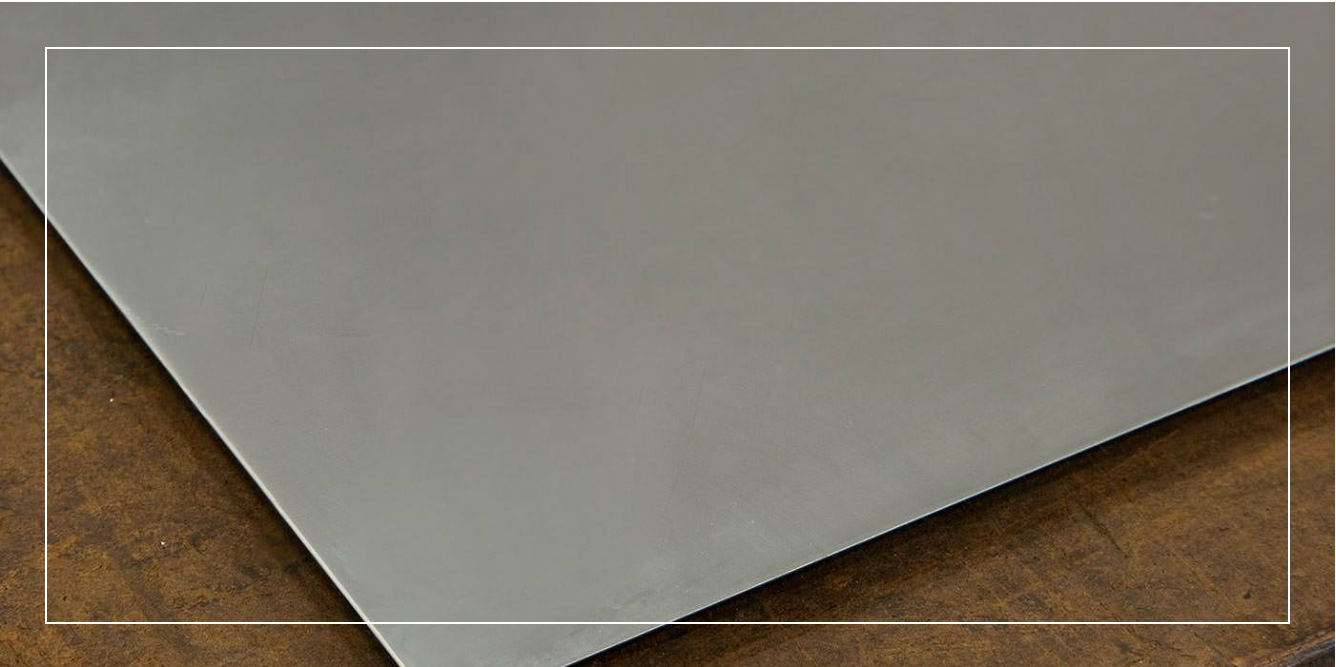

2B finish Stainless Steel Sheet

2B finish is also called “mill finish”, which is one of the most widely used finishes for stainless steel. This mill finish is achieved through a cold-rolling process, followed by annealing and descaling. 2B finish is smooth, but not as reflective as NO.8 mirror finish, so it is used in applications where appearance is not critical.

Categories

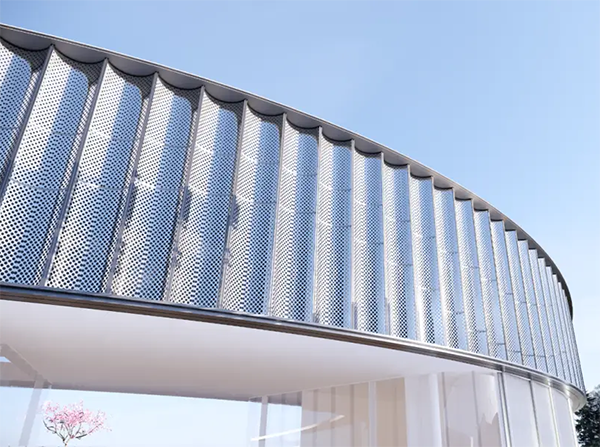

Metal wall facade cladding is exceptional in imbuing architectural projects with both structural integrity and captivating aesthetics. XTT Stainless Steel's facade cladding systems encompass a diverse array of high-quality metal options, each boasting distinct styles. These systems offer paramount protection and adornment。

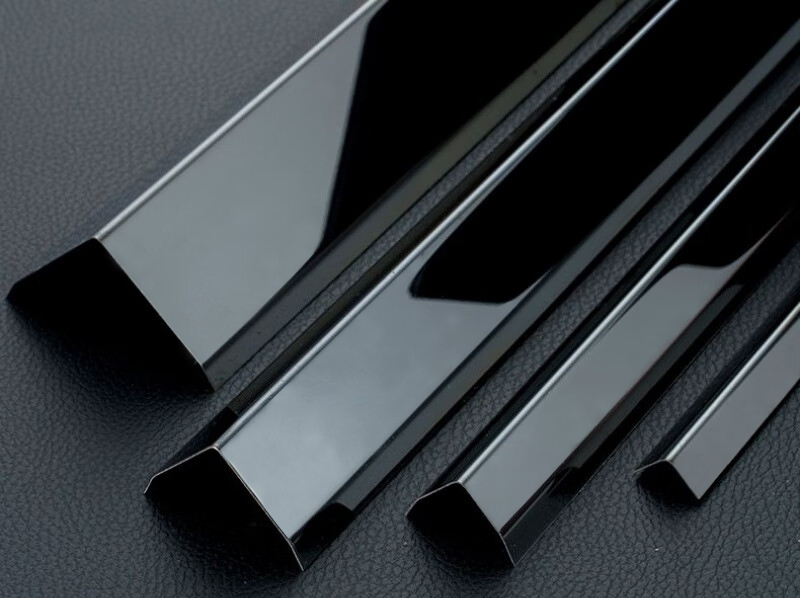

Ti-Black Finish Stainless Steel Sheet

Ti-black finish on stainless steel sheet has two different processes: water plating and electroplating. Water plating is carried out in a chemical electrolyte. Through the accumulation of anions and cations under the action of electric charges, the electrolytic ions with black color gather on the surface of the stainless steel plate, thereby forming the color of black titanium. Electroplating is to form a dense oxide film through the reduction reaction between metal ions in a vacuum plating environment, thereby forming the color of black titanium. The color of water plating is darker than that of electroplating, and the adsorption force of particles on the surface of electroplating is stronger. There is no difference in the use of the plates of the two processes, and both have good reflective effects.

More Details

PVD Finish Stainless Steel Sheet

PVD finish stainless steel sheets refer to a specialized coating onto the stainless steel surface using a vacuum coating technique, offering a range of color options, including gold, rose gold, bronze, black, and other decorative finishes. This makes PVD coated stainless steel suitable for various design applications.

More Details

Applications

for 2B Finish Stainless Steel Sheet

The 2B finish is a versatile surface finish that is found in

various industries due to its characteristics.

Architectural Applications: Due to smooth appearance, 2B

finish stainless steel sheets are widely used for building exteriors and

interiors such as facades, columns, handrails, and decorative panels.

Kitchen Equipment and Appliances: It becomes very

popular while people choose for kitchen countertops and backsplashes due to

easy to clean and maintain. It is also chosen for outer panels of appliances

like refrigerators, ovens, and dishwashers, etc.

Food Processing Equipment: 2B finish stainless steel panels

are suitable for equipment constructions such as tanks, conveyors support, and

processing vessels in industries where requires high hygiene standards.

Automotive Applications: Due to its attractive and

corrosion resistance properties, 2B finish stainless steel can be used for

automotive trim, logos, and decorative elements.

Chemical and Industrial Equipment: 2B finish stainless

steel panel is a good choice for chemical and industrial equipment like tanks

and vessels for storing chemicals or other industrial liquids. In some cases,

it may be used for piping and tubing also.

Signage Applications: 2B finish sheets are commonly

chosen by signage manufacturers for outdoor boards, interior signage letters.

After laser cutting or bending process, with color painted with lighting

decoration, it can get a good effect especially in evening.

Other Applications: This 2B finish panels also can

be used for furniture components for contemporary designs, platforms, and

equipment in the oil and gas industry, or laser-cut parts, etc.

Specifications

for 2B Finish Stainless Steel Sheet

Type: Stainless steel sheet

Type: Stainless steel sheet

Standard: GB, ASTM, AISI, JIS, DIN

Technique: Cold rolled

SS Grade: 201, 304, 316, 430

Finish:

Color: Champagne, Gold, Rose Glod,

Black, Silver, etc.

Edge: Mill or Slit

Thickness: 0.3-3mm

Width: 1000mm, 1219mm, 1240mm, 1250mm,

1500mm, Customized.

Length: Customized (Max.: 6000mm)

Application: kitchen appliances,

automotive components, architectural elements, and industrial equipment

Packing: PVC film + waterproof paper + standard wooden package

Material

Options for 2B Finish Stainless Steel Sheet

2B finish is characterized by a smooth, moderately reflective finish with a dull, non-reflective sheen. When selecting a material for 2B finish stainless steel sheets, the specific requirements of your application, including corrosion resistance, strength, formability and cost should be under consideration. Additionally, you may need to verify the material should also meet any relevant industry or regulatory standards.

201

Stainless Steel Sheet

201

Stainless Steel Sheet

201 type stainless steel is known for its lower cost compared to other grades stainless steel like 304. It is often chosen for its cost-effectiveness and general-purpose corrosion resistance in less demanding environments. 201 2B finish stainless steel sheets are mostly used in kitchen equipment, architectural components, decorative items, or manufacturing industries.

304

Stainless Steel Sheet

304

Stainless Steel Sheet

This

type 304 stainless steel is known for its excellent corrosion resistance,

high-temperature strength, and good formability. And it is mostly used in a

wide range of applications, such as kitchen equipment, chemical containers,

architectural components, and specific industries where a clean, uniform

appearance is desired.

FAQ (frequently asked questions)

1- What is 2B Finish Stainless Steel Sheet?

A 2B finish is characterized by a smooth,

moderately reflective surface. 2B finish stainless steel sheets are widely used

in various applications, including kitchen appliances, automotive components,

architectural elements, and industrial equipment. It reaches a balance between

appearance and cost, suitable for situations where a smooth, clean finish is

required, but the highest level of reflectivity is unnecessary.

2- Is A Protective Film Required on 2B Finish Stainless Steel Sheets?

Normally

a protective film is not always required for 2B finish stainless steel sheets.

But in some cases, it is necessary to put a protective film on mill finish

sheets. When the stainless steel sheets will be transported before

installation, a protective film can help prevent scratches, abrasions, or other

damages. The mill finish stainless steel sheets are used in fabrication

processes, where they will be cut, bent, or other process. A protective film also

can help preserve the finish in these operations. So it depends on different

applications where to be used.

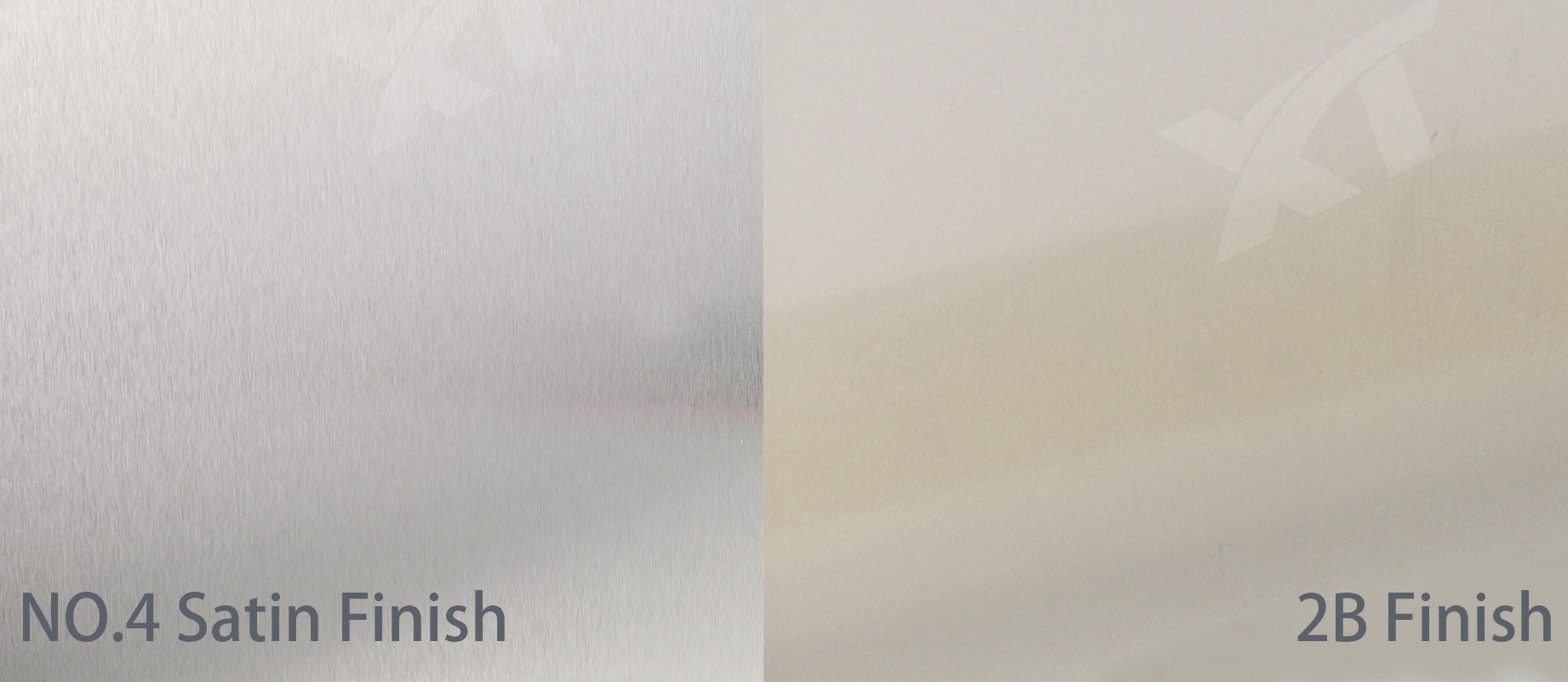

3- What Is the Difference Showing on Stainless Steel Between 2B Finish and NO.4 Satin Finish? How To Choose the Proper Finish?

2B finish shows the smooth, moderately

reflective with a clean appearance. No. 4 satin finish shows matte with visible

grain lines, providing a textured finish, which helps conceal minor scratches

and wear, and make it in wide range applications. In summary, the choice

between 2B finish and No.4 satin finish depends both on the aesthetic and

functional requirements.

2B finish shows the smooth, moderately

reflective with a clean appearance. No. 4 satin finish shows matte with visible

grain lines, providing a textured finish, which helps conceal minor scratches

and wear, and make it in wide range applications. In summary, the choice

between 2B finish and No.4 satin finish depends both on the aesthetic and

functional requirements.

4- Is 304 2B Finish Better Than 201 2B Finish?

Due

to higher chromium and nickel content, 304 2B finish is more

corrosion-resistant and durable than 201 2B finish. Moreover 304 shows a

smoother and more reflective appearance than 201, which makes it suitable for

clean and aesthetically pleasing surface. But the cost of 304 2B finish

stainless steel sheets are also more expensive than 201 2B finish stainless

steel sheets. If cost is a primary concern and the application is not in high

level requirement, then 201 stainless steel sheets with 2B finish could be

better, and vice versa.

5- Can 2B Finish Stainless

Steel Sheets be Hard Anodized?

Yes, we can anodize stainless steel to

different colors, including black. But colors by anodizing are not durable as

those by other treatments, like PVD coated and water plating, especially for

black color. While selecting the treatment for mill finish stainless steel

panels, the applications should be one of the most important factors to be

considered.

Latest Posts

Why Are More And More People Installing Stainless Steel Countertops?

If you rarely cook and the kitchen is more of a show space for you, then you may only need to focus on whether the countertops meet your aesthetic standards and overall decoration style. If you are a cooking enthusiast

What is Perforated Sheet? How Important Does Perforated Sheet Play Role In Decor

A perforated sheet is a metal sheet that has been punctured with a series of holes in a pattern. These holes can vary in size, shape, and distribution, depending on the intended application. Perforated sheets are commonl

2024 Trend of Overall Stainless Steel Kitchen Cabinets

The latest report released by the National Kitchen and Bathroom Association (NKBA) provides a detailed overview of the cutting-edge trends in kitchen design in 2024. According to NKBA's research, the minimalist design co

Export Stainless Steel Sheets To Bangladesh

Export 201 Hot-Rolled Stainless Steel Sheets, Cold-Rolled Stainless Steel Sheets, 8K Mirror Finish Stainless Steel Sheets to Bangladesh.