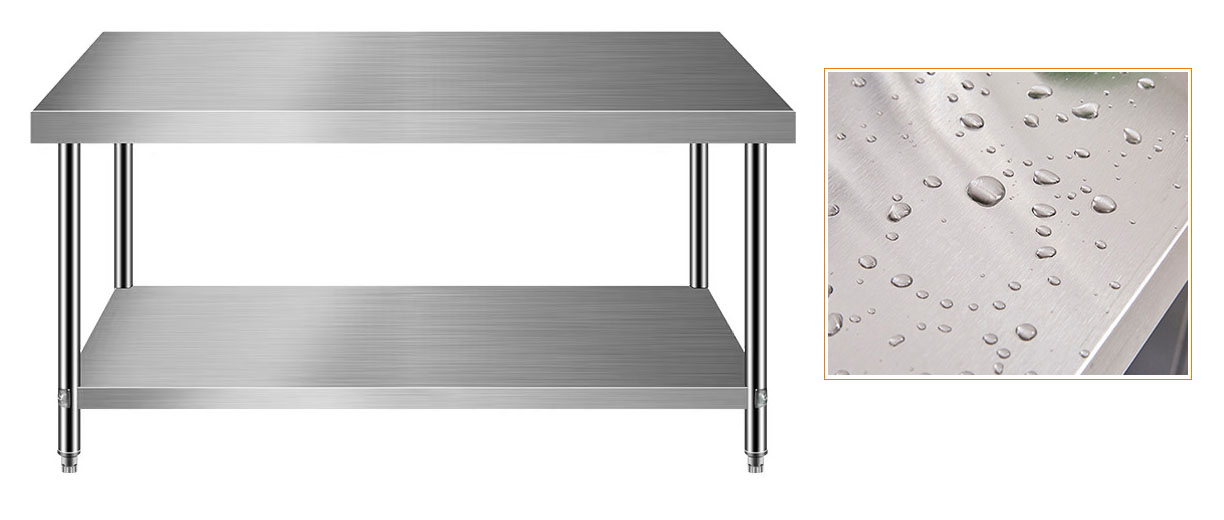

Commercial Kitchen Countertop

A commercial kitchen countertop is a work surface specially designed and constructed for use in professional kitchens, and those are found in restaurants, hotels, catering businesses, and other food service establishments. It has a high requirement about scratches and stains resistance, heat resistance, easy to clean and sanitize, therefor stainless steel countertop becomes the best choice for commercial kitchens.

Categories

Everyone who works in a commercial kitchen has to be hardworking, and the same applies to the kitchen facilities and equipment! Heat, humidity, acid and many other things are wearing down the surfaces of various facilities, which makes stainless steel as an irreplaceable material in the commercial kitchen.

Commercial Kitchen Sink

A commercial kitchen sink is specially designed for use in commercial or professional kitchen environments. Due to various tasks, single-basin, double-basin, and three-compartment sinks can be found in commercial kitchen to meet specific demands of high-volume and intensive use typical of restaurants, catering facilities, hotels, hospitals, etc. Size and capacity of stainless steel sinks also can be designed as kitchen layouts. Besides, various installation types, including undermount, drop-in, and wall-mounted sinks, show flexibility in design. Some additional features such as drainboards, pre-rinse spray units, and integrated backsplashes, improve the efficiency in a commercial setting.

More Details

Commercial Kitchen Backsplash

A commercial kitchen backsplash is a protective wall covering typically installed behind cooking surfaces, such as stoves, ovens, and food preparation areas in commercial kitchens. It can protect the wall from splatters, grease, and other cooking-related messes, which makes for easier cleaning as the smooth surface.

In commercial kitchen settings, hygiene and cleanliness are in highly important. Therefore, stainless steel backsplashes are often chosen for durability, stains resistance, and ease of cleaning.

Besides functionality, commercial kitchen backsplashes are designed to meet health and safety regulations.

More Details

Applications and Benefits of Commercial Kitchen Countertops

The applications of commercial kitchen countertops are diverse for food preparation and cooking in restaurants, hotels, or other public places. Here are some key applications:

Food

preparation:

Food

preparation:

l Chopping and Cutting: countertops provide a

dedicated space for chopping, cutting, and preparing ingredients for cooking.

l Assembly and Plating: Chefs use them to assemble dishes and plate meals before serving.

Cooking

Surfaces:

l Placement of Cooking Equipment: It can be

used for keeping cooking appliances such as stoves, ovens, grills, and fryers.

l Hot Pans and Pots: Hot cookware can be placed directly on heat-resistant countertops during cooking.

Dishwashing: Countertops near sinks are used for washing and rinsing dishes, utensils, and kitchen tools.

Storage and Organization: Countertops provide temporary storage for ingredients, utensils, and equipment during the cooking process.

Display and

Service:

l Stainless steel countertops in commercial

kitchens are used to showcase prepared foods.

l Service Counters: In restaurant kitchens, countertops may be used as service counters where dishes are plated for serving.

Customization for Workflow: Customized countertops are designed to optimize the kitchen layout, including specific areas for tasks like baking, pastry preparation, or butchery.

Specifications for Commercial Kitchen Countertop

Type: Stainless steel

sheet

Type: Stainless steel

sheet

Standard: GB, ASTM,

JIS, DIN

Technique: Cold

rolled

SS Grade: 201,

304, 316

Finish: Polished,

Brushed, Satin, Mirror, Embossed, etc.

Edge: Mill or Slit

Thickness: 0.8-3mm

Width: Customized

Length: Customized

Application: Commercial

restaurants, hotels, catering businesses, etc.

Packing: PVC film

+ waterproof paper + standard wooden package

Surface

Finishes for Stainless Steel Commercial Kitchen Countertops

While selecting a

surface finish for SS commercial kitchen countertops, it’s important to

consider both aesthetic preferences and practical features as maintenance and

durability, which should align with the design and the demands of the

commercial environment.

Polished Finish

A polished finish countertop

involves a high shine and smooth surface. However, it shows scratches, smudges,

and water spots easily. So regular cleaning in proper way is essential to keep

it looking well. Moreover, the cost for

polished finish SS countertops is more expensive than some other finishes.

Satin Finish

Satin finish

countertops have matte appearance, which makes it as a practical choice for

busy commercial kitchens. And satin finish kitchen countertops are more

cost-effective than that in polished finish, making them an attractive choice

for commercial settings.

Pattern Finish

Pattern finish

countertops can add a distinctive and visually interesting element to the

commercial kitchens. SS countertops in patterns can hide scratches, dings, and

wear over time. However, during the cleaning, pattern countertops may pose

challenges. And the cost for pattern involves additional costs in comparation

with other standard finishes.

Textured

finish

Textured finish

countertops can enhance safety, reducing the risk of slips and falls due to

enhanced grip. But the level of textured finish should be considered to ensure

it doesn’t hinder the ease of food preparation cleaning. It’s mostly chosen by

experienced designers and fabricators.

FAQ (frequently

asked questions)

1- What Are the Common Materials Used for

Commercial Kitchen Countertops? And What Are the Advantages and Disadvantages of

Them?

Today, we will

discuss the common materials for commercial kitchen countertops, which need to

be durable, resistant to heat, stains, and easy to clean. There are some

materials concerned:

1)

Stainless

steel: It is also the most

popular choice for countertops in commercial kitchens due to its basic

characteristics. Stainless steel commercial kitchen countertops are resistant

to bacteria, making it a hygienic option. Despite being durable, they are also

quite prone to dents. Kindly remind not cut anything on the countertops directly,

as it can be damaged.

2)

Quartz: Engineered quartz countertops is known as artificial

quartz countertops, which is highly durable, non-porous, low-maintenance, and

extremely tough. They also come in a variety of colors and patterns that show

similar look as natural materials. But quartz countertops can not resistant to

high temperatures, so it is not recommended boiling pots or pans on them.

3)

Granite: Natural granite provides a high-end look

and can be available in various colors and patterns due to its durability and

resistance to heat and scratches. Its natural surface makes it a great material

for residential countertops. But for commercial countertops, it is not popular

as stainless steel due to the cost and other factors.

4)

Laminate:

laminated countertops are

made by a paper or fabric on top of particleboard, which comes in different

patterns or colors. However, they are more susceptible to scratches and heat

damage comparing to other materials.

5)

Other

materials: Apart from

above material mentioned, there are Corian countertops, wooden countertops,

concrete countertops or tiles. In summary, while selecting a proper material

for commercial kitchen countertop, it’s important to consider both their

benefits and drawbacks according to your requirements.

2- Which Grade is Used Mostly for Stainless

Steel Countertops? And Why?

Type 304 is the most common grade for stainless steel commercial kitchen countertops. Its composition makes it highly resistant to corrosion and oxidation. And it could withstand exposure to acids, alkaline solutions, and high temperatures. Apart type 304, some applications may call for higher-grade stainless steels as Type 316, which contains additional molybdenum, providing increased resistance to corrosion, especially in environments with exposure to chlorides. While choosing stainless steel kitchen countertops, it’s necessary to consider both specific requirements and budget.

3- What Finishes Are Used for SS Commercial

Kitchen Countertops? And Why?

SS commercial kitchen countertops

can have different finishes depending on both functional and aesthetic

considerations. It includes:

1)

Brushed

(or Satin) Finish: brushed

or satin finish has a matte appearance, which helps hide scratches and

fingerprints, providing a contemporary and industrial look.

1)

Brushed

(or Satin) Finish: brushed

or satin finish has a matte appearance, which helps hide scratches and

fingerprints, providing a contemporary and industrial look.

2)

Polished

Finish: The polished

finish SS countertop has got a reflective and smooth appearance. However, it

may show scratches and fingerprints easier than brushed finish.

3)

Textured

Finish: Textured finishes

such as hammered or embossed patterns provide a unique and decorative look,

which can add visual interest and help mask scratches and wear.

4)

Pattern

Finish: SS kitchen

countertops come in pattern finish also, such as diamond plate or other

geometric designs, adding a distinctive style.

5) Antimicrobial Finish: Some commercial kitchen countertops are treated with antimicrobial coatings to inhibit the growth of bacteria and other microorganisms, enhancing hygiene.

4- How Long Do SS Commercial Kitchen

Countertops Last?

High-grade SS countertops as Type

304 can contribute to a longer lifespan. SS countertops for commercial kitchen

are much thicker than that for residential kitchen due to withstand heavy use.

The frequency and type of use, as well as the conditions in the kitchen

environment, can impact the lifespan of SS commercial kitchen countertops. In

summary, proper care and maintenance can last for several decades.

5- Are Stainless

Steel Countertops Customized?

Yes, certainly. They can be

customized to meet the specific required, which allows flexibility in terms of

dimensions, features, and finishes. It’s easy to understand why to custom the

exact dimensions for countertops in kitchen or workspace. In variety of edge

profiles, like square, beveled, bullnose, or custom designs, also can be

customized to achieve a specific look or meet functional demands. Sink

integration and other fixtures should be considered while making countertops.

There are various surface finishes for options, such as brushed, polished,

textured, or patterned as well as thickness.

Surface Finishes

While selecting a surface finish for SS commercial kitchen countertops, it’s important to consider both aesthetic preferences and practical features as maintenance and durability, which should align with the design and the demands of the commercial environment.

Latest Posts

Why Are More And More People Installing Stainless Steel Countertops?

If you rarely cook and the kitchen is more of a show space for you, then you may only need to focus on whether the countertops meet your aesthetic standards and overall decoration style. If you are a cooking enthusiast

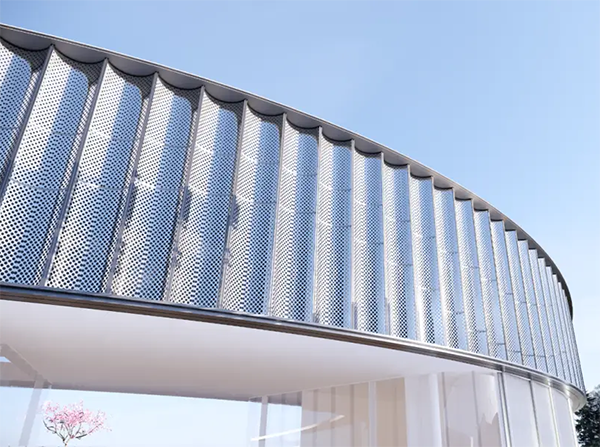

What is Perforated Sheet? How Important Does Perforated Sheet Play Role In Decor

A perforated sheet is a metal sheet that has been punctured with a series of holes in a pattern. These holes can vary in size, shape, and distribution, depending on the intended application. Perforated sheets are commonl

2024 Trend of Overall Stainless Steel Kitchen Cabinets

The latest report released by the National Kitchen and Bathroom Association (NKBA) provides a detailed overview of the cutting-edge trends in kitchen design in 2024. According to NKBA's research, the minimalist design co

Export Stainless Steel Sheets To Bangladesh

Export 201 Hot-Rolled Stainless Steel Sheets, Cold-Rolled Stainless Steel Sheets, 8K Mirror Finish Stainless Steel Sheets to Bangladesh.