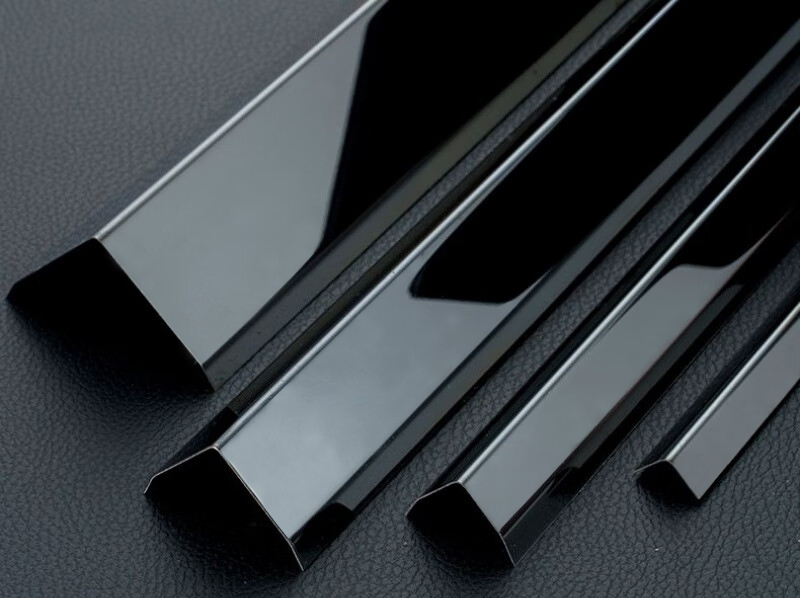

NO.8 Mirror Finish Stainless Steel Sheet

Mirror finish stainless steel sheets refer to a polished & highly-reflective surface on stainless steel sheets or plates, which is achieved through a series of abrasive and polishing processes. This type of finish typically involves finer abrasives. Buffing and polishing compounds are often used in conjunction with abrasive materials to enhance the reflective quality of the surface. Mirror finish stainless steel sheets are mostly used in decorative applications, which makes surface create a sleek and modern appearance for various aesthetic purposes. Apart from this, the surface of mirror finish stainless steel sheets is easier to clean and maintain than surfaces of other rough texture.

Categories

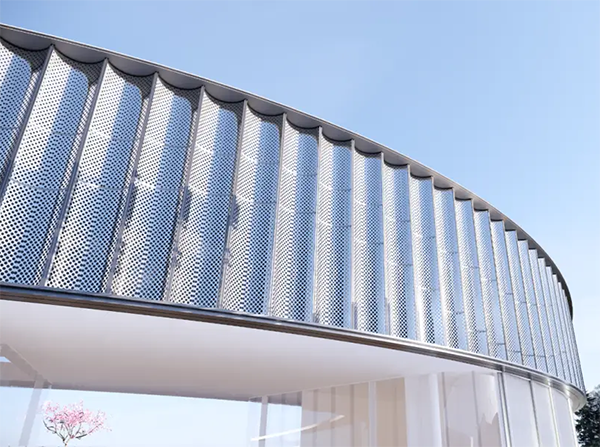

Metal wall facade cladding is exceptional in imbuing architectural projects with both structural integrity and captivating aesthetics. XTT Stainless Steel's facade cladding systems encompass a diverse array of high-quality metal options, each boasting distinct styles. These systems offer paramount protection and adornment。

Ti-Black Finish Stainless Steel Sheet

Ti-black finish on stainless steel sheet has two different processes: water plating and electroplating. Water plating is carried out in a chemical electrolyte. Through the accumulation of anions and cations under the action of electric charges, the electrolytic ions with black color gather on the surface of the stainless steel plate, thereby forming the color of black titanium. Electroplating is to form a dense oxide film through the reduction reaction between metal ions in a vacuum plating environment, thereby forming the color of black titanium. The color of water plating is darker than that of electroplating, and the adsorption force of particles on the surface of electroplating is stronger. There is no difference in the use of the plates of the two processes, and both have good reflective effects.

More Details

PVD Finish Stainless Steel Sheet

PVD finish stainless steel sheets refer to a specialized coating onto the stainless steel surface using a vacuum coating technique, offering a range of color options, including gold, rose gold, bronze, black, and other decorative finishes. This makes PVD coated stainless steel suitable for various design applications.

More Details

Applications of Mirror Finish Stainless Steel Sheet

Mirror finish stainless steel sheets are found in various industries and settings due to their attractive appearance, durability, and corrosion resistance. It includes architectural and interior design, especially for wall coverings, elevator interiors, column covers, ceiling panels, apart from this, it is widely used for decorative features in different industries, such as furniture, lightings, signage, jewelry and art, retail displays, marine applications, etc.

These applications showcase the versatility of mirror finish stainless steel sheets in enhancing aesthetics and providing a clean, modern look. Additionally, the corrosion resistance makes it suitable for both indoor and outdoor applications.

Advantages of Mirror Finish Stainless Steel Sheet

Mirror stainless steel sheets have a highly polished surface, and they are versatile, which makes them to be a very popular choice for architectural and interior design and applications.

Mirror stainless steel sheets is known for its durability and corrosion resistance, which makes them suitable for both indoor and outdoor applications, and its durability contributes to a longer service life and reduced maintenance cost.

Mirror polished stainless steel sheets are easy to clean and maintain, which is suitable for environments where cleanliness is essential, such as kitchens and bathrooms.

The reflective nature of mirror finish stainless steel enhances brightness in spaces, likes lighting fixtures, where increased light reflection contributes to a brighter environment.

Generally stainless steel sheet has good temperature resistance, and the mirror polishing process doesn’t negatively impact this property. So it is suitable for applications where exposure in high or low temperatures.

Specifications

of Mirror Finish Stainless Steel Sheet

Type: Stainless steel sheet

Standard: ASTM,

AISI, GB, JIS, DIN

Technique: Cold

rolled

SS Grade: 201,

304, 316, 430

Finish: NO.8

mirror finish

Edge: Mill or Slit

Thickness:

0.22-2.5mm

Width: 1219mm,

1240mm, 1250mm, 1500mm

Length: Optional (Max:

6000mm)

Color: Silver,

Rose gold, Champagne gold, Black, Blue, Copper

Application: ceiling,

wall coverings, shower plates, elevator panels,

Packing: PVC film

+ waterproof paper + standard wooden package

Color options

for Mirror Finish Stainless Steel Sheet

Stainless steel sheets are typically available in a natural metallic color, which is silver finish. However, decorative stainless steel sheets can be treated or coated to achieve different colors or finishes, such as rose gold, champagne gold, black, blue, cooper for different applications. Some common methods for coloring stainless steel include Physical Vapor Deposition (PVD), Water Plating, Electroplating, Painting or Powder coating, which provides options as customer’s requirements or intended application.

FAQ

(frequently asked questions)

1- Where Can Mirror Finish Stainless Steel Be Used?

The mirror finish is mostly used

some places where a highly reflective and smooth surface is desired, such as automotive

industry as trim, wheels, architectural and decorative applications like

elevator doors, wall panels and handrails, household items like kitchen

appliances and faucets, jewelry items, consumer electronics as smartphones,

tablets, and laptops, medical instruments, optical components, watchmaking, and

aerospace industry.

2- Is It Very Difficult to Maintain the Mirror Finish Stainless Steel Sheets?

Comparation with

brushed or satin finish maintenance, it is a little difficult to maintain appearance

for mirror finish sheets. It’s easy to show fingerprints and smudges, which

requires regular cleaning. To avoid abrasive material and harsh chemicals are

also necessary. Do consider professional cleaning for mirror finish sheets.

3- Can Stainless Steel be Used as A Mirror?

Yes, stainless steel can be used as a mirror surface, and often utilized in a reflective and polished finish, such as building facades, decorative panels, wall panels, elevator interiors, art and sculptures to create visually striking and reflective pieces.

4- What’s the Full Process for Mirror Finish

Stainless Steel Sheets?

First step is to cut the sheets

into the desired size and shape. Coarse grinding is the second step to remove

any imperfections, scratches or welding marks by abrasive grinding wheels or

belts. The 3rd step is to sand with progressively finer grit

abrasives. Buffing using softer materials like felt wheels along with polishing

compounds achieve a higher level of reflectivity. The final polishing stage is

critical in achieving the mirror finish. After that, clean and remove polishing

compounds, residues, or contaminants are necessary. And some mirror-finished

stainless steel sheets may require a protective coating to enhance durability

and resistance to fingerprints.

Color Options

Latest Posts

Why Are More And More People Installing Stainless Steel Countertops?

If you rarely cook and the kitchen is more of a show space for you, then you may only need to focus on whether the countertops meet your aesthetic standards and overall decoration style. If you are a cooking enthusiast

What is Perforated Sheet? How Important Does Perforated Sheet Play Role In Decor

A perforated sheet is a metal sheet that has been punctured with a series of holes in a pattern. These holes can vary in size, shape, and distribution, depending on the intended application. Perforated sheets are commonl

2024 Trend of Overall Stainless Steel Kitchen Cabinets

The latest report released by the National Kitchen and Bathroom Association (NKBA) provides a detailed overview of the cutting-edge trends in kitchen design in 2024. According to NKBA's research, the minimalist design co

Export Stainless Steel Sheets To Bangladesh

Export 201 Hot-Rolled Stainless Steel Sheets, Cold-Rolled Stainless Steel Sheets, 8K Mirror Finish Stainless Steel Sheets to Bangladesh.