Bending Methods For Stainless Steel

Stainless

steel, being a versatile and durable material, can be bent using several

methods depending on the thickness, grade, and desired outcome. Here are some

common bending methods for stainless steel:

u Cold

Bending:

This method involves bending stainless steel at room temperature. It's suitable

for thin sheets and small parts. Cold bending can be done manually or using

equipment like a press brake, which applies force to bend the metal. However,

it's important to note that stainless steel has higher strength and work

hardening properties compared to other metals, so more force may be required.

u Roll

Bending:

Roll bending involves passing stainless steel through sets of rollers to

gradually bend it into the desired shape. This method is often used for

cylindrical or curved shapes, such as tubes or pipes. It's suitable for both

thin and thick sections of stainless steel.

u Hot

Bending:

Hot bending involves heating the stainless steel to high temperatures (usually

around 1000-1200°C) before bending. Heating reduces the material's strength and

makes it more malleable, allowing for easier bending without risk of cracking.

Hot bending is commonly used for thick sections or complex shapes.

u Induction

Bending:

This method utilizes induction heating to heat specific areas of the stainless

steel before bending. It's suitable for large diameter pipes and tubes.

Induction bending allows for precise control over the bending process and

minimizes distortion.

u Press

Brake Bending: A press brake is a machine tool equipped with a flat bed

and a V-shaped or U-shaped die. The stainless steel sheet is placed on the bed,

and a punch presses down to bend it against the die. Press brake bending is

commonly used for producing straight bends and angles in stainless steel sheets

and plates.

u Air

Bending:

In air bending, the stainless steel sheet is bent by applying force using a

punch, but it doesn't fully contact the die, leaving a small gap. This method

allows for greater flexibility in bending angles and reduces the risk of

damaging the material.

u Coining: Coining

is a precision bending method used to produce sharp bends or intricate shapes

in stainless steel. It involves applying high pressure to the material using a

specially designed die and punch set.

u Rotary

Draw Bending: This method involves clamping one end of a stainless

steel tube or pipe and drawing it around a die while simultaneously bending it.

Rotary draw bending is commonly used for producing tight-radius bends with

minimal distortion.

u Mandrel

Bending:

Mandrel bending utilizes a mandrel (a rod or flexible rod inserted into the

tube or pipe) to support the inner wall of the stainless steel during bending.

This method helps prevent wrinkling or collapsing of the tube or pipe and is

often used for producing smooth bends in stainless steel tubing.

Before performing any bending operation, it's crucial to consider factors such as the grade and thickness of the stainless steel, the desired bend radius, and the tolerances required for the finished product. Additionally, proper safety measures should always be followed to prevent accidents and ensure quality results.

Which Specification Is Suitable For Bending?

The

choice of specification for bending stainless steel depends on several factors,

including the grade of stainless steel, the thickness of the material, the type

of bending method being used, and the specific requirements of the application.

Here are some considerations:

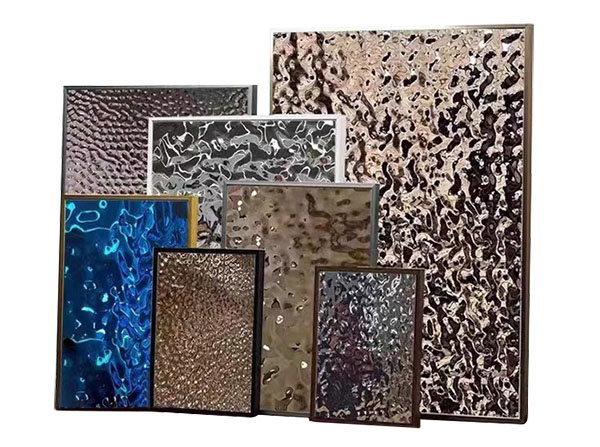

Grade of

Stainless Steel: Different grades of stainless steel have varying mechanical

properties, including hardness, strength, and ductility. Austenitic stainless

steels (such as 304 and 316) are generally more ductile and easier to bend than

martensitic or duplex stainless steels. Therefore, austenitic grades are often

preferred for bending applications.

Thickness

of Material: Thinner sheets and plates are generally easier to bend than

thicker ones. However, even within the same grade, thicker sections may require

specific bending methods or preheating to achieve the desired bend without

cracking or excessive deformation.

Bending

Method: Certain bending methods may be better suited for specific stainless

steel specifications. For example, cold bending can be used for most stainless

steel grades and thicknesses, while hot bending or induction bending may be

necessary for thicker sections or complex shapes.

The

Technical Performance Of Stainless Steel Sheets

1) Because

the thermal conductivity is worse than ordinary low carbon steel and the

elongation is low, the required deformation force is large;

2) 321

stainless steel sheet has a strong rebound tendency compared with carbon steel

when bent;

3) Due to

the lower elongation of stainless steel plates compared to carbon steel, the

bending angle R of the workpiece during bending must be greater than that of

carbon steel, otherwise cracks may occur;

4) Due to

the high hardness of SUS304 stainless steel plate and the significant cold work

hardening effect, when selecting a press bending tool, you must choose a tool

steel with a heat treatment hardness of above 60HRC. Its surface roughness is

an order of magnitude higher than that of carbon steel press bending tools.

How

To Bend Stainless Steel Sheets?

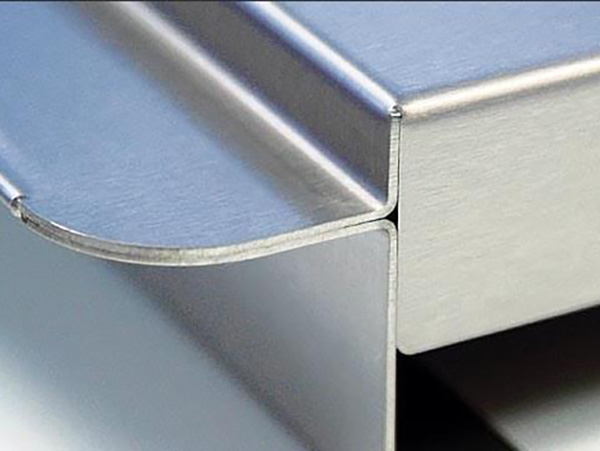

Ø Under

unit size, the thicker the plate, the greater the required bending force, and

as the plate thickness increases, the margin for bending force should be

greater when selecting bending equipment;

Ø Under

unit size, the greater the tensile strength, the smaller the elongation, the

greater the required bending force, and the larger the bending angle should be;

Ø When the

plate thickness corresponds to the bending radius in the design drawing,

according to experience, the expansion size of a bent workpiece is the sum of

the right-angled sides minus the two plate thicknesses, which can fully meet

the design accuracy requirements. The expansion amount can be calculated

according to the empirical formula. Simplifying the calculation process greatly

improves production efficiency;

Ø The

greater the yield strength of the material, the greater the elastic recovery.

In order to obtain a 90-degree angle for the bent part, the angle of the

required press knife must be designed to be smaller. Compared with carbon

steel, stainless steel with the same plate thickness has a larger bending

angle. Special attention should be paid to this point, otherwise bending cracks

will occur and affect the strength of the workpiece.

Ø Because

the thermal conductivity is worse than ordinary low carbon steel and the

elongation is low, the required deformation force is large; 321 stainless steel

sheets have a strong rebound tendency compared with carbon steel when bending;

stainless steel sheets have a strong rebound tendency compared to carbon steel

due to the elongation Low, the bending angle R of the workpiece must be larger

than that of carbon steel during bending, otherwise cracks may occur.

Ø Due to

the high hardness of stainless steel plates and the significant cold work

hardening effect, when selecting press bending tools, you must choose tool

steel with a heat treatment hardness of above 60HRC. Its surface roughness is

an order of magnitude higher than that of carbon steel press bending tools.

How To Bend

Stainless Steel Pipes?

Bending stainless

steel pipes can be achieved using several methods, depending on factors such as

the pipe diameter, wall thickness, bend radius, and desired precision.

There are 2

different bending methods: cold bending and hot bending. Bending at room

temperature is called cold bending and it is often done by a fitter. Heat

bending involves heating the

stainless steel pipe to high temperatures before bending. Heat bending reduces

the material's strength and allows for easier deformation. When the workpiece

is thick (half of it exceeds 5mm), it needs to be bent under heating, which is

called hot bending and is often completed by a forger. This method is suitable

for thicker pipes and complex bends.

There are manual bending and mechanical bending.

Manual Bending: Suitable for small-diameter pipes and simple

bends. This method involves using a pipe bender or bending tool to gradually

bend the pipe to the desired angle.

Mechanical Bending: Utilizes machinery such as a hydraulic or

manual pipe bender. Mechanical bending is suitable for larger diameter pipes

and tighter bends.