What’s The Advantages of Colored Stainless Steel Sheets?

Any product attracts people's attention and love has its advantages, and colored stainless steel sheets are without exception. It is not unreasonable for colored stainless steel sheets to stand out among many decorative materials, because compared with decorative materials such as wood boards and stones, colored stainless steel sheets have incomparable advantages:

More natural, healthier and more

environmentally friendly

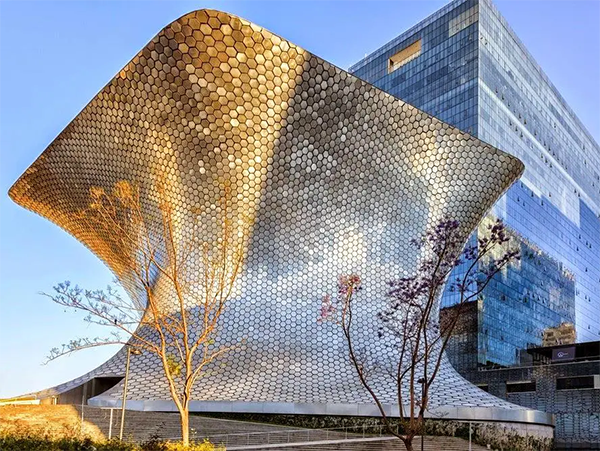

The stainless steel sheets selected by XTT stainless steel can show high-end and stability in the most authentic appearance. They can offer unlimited imagination and creativity in the design of interior decoration, providing a good foundation for decoration. Giving new meaning and beauty can make the architectural design more humane, practical and modern, creating a new trend in decoration and leading the new trend of colored stainless steel sheets.

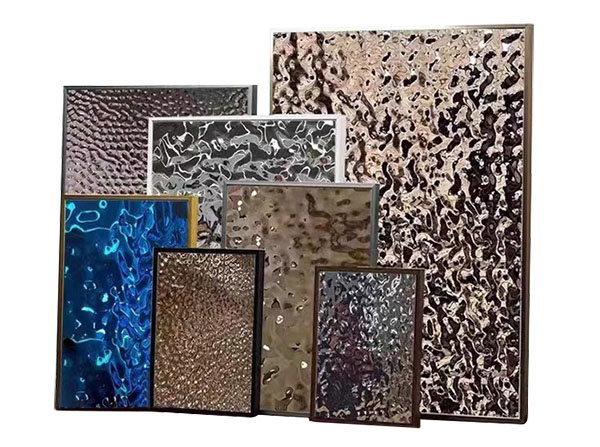

Unique personality style

The series of colored stainless steel plates produced by XTT have various styles, which can present a noble and elegant feeling. Moreover, the colored stainless steel sheets retain the metallic texture of the original color sheets, and have their own unique colorful characteristics, so they can be used in various decorations such as ceilings and walls.

With a value-preserving function

The colored stainless steel sheets of XTT can allow for a warm and harmonious feeling in decoration, so they are very popular and loved by consumers and engineering contractors. Colored stainless steel sheets have their free natural texture, changeable shapes, and various color options. Therefore, the value of colored stainless steel sheets in space decoration will be better than other general decorative materials.

Longer service life

The colored stainless steel sheets purchased on the market may vary in quality, so generally speaking, their service life is not long. However, the service life of XTT colored stainless steel sheets is guaranteed to be 5 times or even more, because our company's base materials are made from well-known domestic steel manufacturers. For sales, the quality is more guaranteed. And you only need to make daily maintenance, then can get a new look all the time.

Comprehensive cost-effectiveness

XTT is conducting new research and exploration, and committed to realizing the transformation of the production of colored stainless steel products and breakthroughs in production technology, with a hard-working spirit, enterprising spirit and considerate and thoughtful service. Create a better future with customers.

How are Colored Stainless Steel Sheets

Colored? And Why Can They be So Colorful?

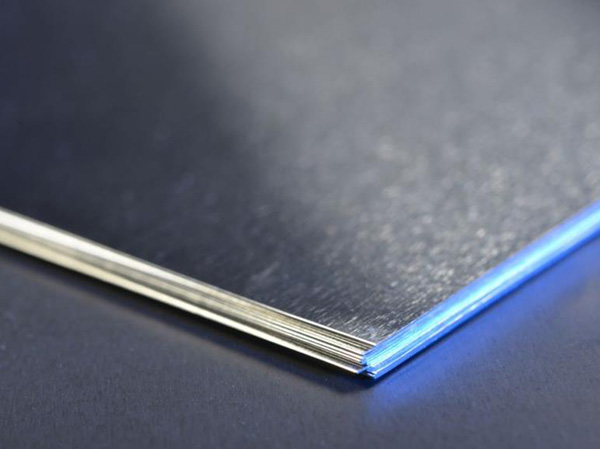

In fact, this is all due to the PVD

vacuum process. Through this process, the surface of the stainless steel sheet

can be formed into various colors, including red, orange, yellow, green, blue,

and purple, which has greatly expanded its application fields.

The vacuum ion plating coloring method

is a processing method in which metal is heated to melt and evaporate under

high vacuum conditions, and the heated metal is cooled on the surface of the

stainless steel raw material to form a surface film. Commonly used metals are

low melting point metals such as titanium. During the vacuum ion plating

coloring process of stainless steel sheets, there are two main methods of

heating the metal. One is to use heat energy generated by resistance, and the

other is to use electron beams.

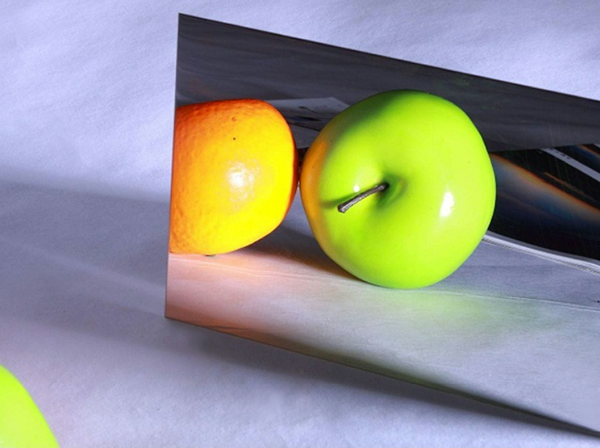

When coating and coloring a stainless

steel sheet, the surface must first be processed, such as a polished mirror

panel, a brushed or a sandblasted finish, etc. The passivation film on the

original surface of the stainless steel sheet must be removed, and time must be

processed. Adjustment. Place the stainless steel plate in the vacuum chamber,

select some heated materials to be plated and titanium metal, use low-voltage,

high-current arc discharge technology, use gas discharge to evaporate the

target and ionize the evaporated substances and gases, and use the acceleration

of the electric field The evaporated substance and its reaction products are

deposited on the workpiece.

Titanium metal interacts with various gases in vacuum ion plating equipment to form plasma. After acceleration, the plasma rushes to the surface of the workpiece to be plated, forming a strong film layer. The titanium-coated stainless steel sheet has a fine and uniform layer, strong bonding force, high hardness, anti-corrosion and wear resistance, good conductivity and self-lubricating properties, and rich and diverse colors. By adjusting relevant parameters during the process, different colors can be made. Therefore, the colored stainless steel titanium-plated sheets are not only golden, but also have other colors, which can be customized and processed according to customer requirements.

Several Situations in Which Colored

Stainless Steel Sheets Will be Corroded

In recent years, colored stainless steel sheets can be known to be a new star in the decoration industry. They are widely favored by customers for their beautiful colors, excellent anti-corrosion, easy processing and other characteristics. But do you know? Colored stainless steel sheets can also cause corrosion if used improperly, which is not necessarily a quality problem with the plates.

Where To Be Used?

If it is in a relatively humid coastal area, colored stainless steel plate products exposed outdoors are most susceptible to chronic corrosion. Because sea water evaporates, humid air and rainwater carrying a relatively large amount of salt cover the surface of the plate, and galvanic corrosion occurs. This corrosion process is relatively slow due to the relatively weak environment and is generally not easy to detect. But over time, it will cause damage to the surface of the board.

There are also big reasons for the choice of material: the most common colored stainless steel plate products on the market are made of 201 or 304. Due to the difference in nickel content, the anti-corrosion performance of 304 stainless steel is much higher than that of 201. Therefore, if it is used indoors, you can consider the cheaper 201 stainless steel, but for outdoor use, 304 stainless steel are preferred.

Human reasons also exist: some detergent products may be used during the cleaning process.

Today's cleaning agents may be more or less weakly acidic or weakly alkaline.

Since these cleaning agents remain on the surface of the colored stainless

steel sheet and are left in this environment for a long time, the surface of

the colored stainless steel sheet will be chronically corroded. Therefore, in

daily cleaning, just wipe it with a soft cloth dipped in water. Try not to use

strong detergents with chemical ingredients. If you use detergent, be sure to

remove the remaining stains.

XTT has been engaged in the stainless steel industry for 15 years and has become a leader in the stainless steel industry. It mainly sells 304 stainless steel sheets, 201 stainless steel sheets, 316 stainless steel sheets, stainless steel decorative sheets, mirror stainless steel sheets, colored stainless steel sheets, etc. Leading the R&D, production, sales, warehousing and logistics system services of stainless steel products.

If you have any requirement, pls feel

free to contact us.