How to Choose Proper Protective Film for

Stainless Steel Sheets?

With the development of my country's industry, stainless steel sheets and coils are widely used in various industrial fields and building decoration. The purpose of protective film is to protect the surface of stainless-steel sheets during transportation and further production. Always protect the processed stainless-steel surface.

Main Categories of Stainless Steel Protective Films

l Material classification of stainless-steel protective film: PVC

film, PE film, PET film, etc.

l Classify the stainless-steel protective film by use: laser film,

stretch film, color plate base film, ordinary stainless steel protective film,

etc.

l Stainless steel protective film thickness classification: 3C, 5C,

7C, 10C, etc. represent 30mirco, 50mirco, 70mirco, 100mirco, etc.

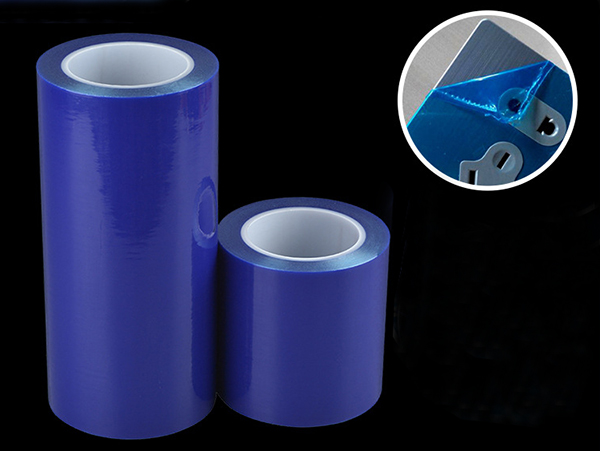

l Stainless steel protective film appearance classification: blue

film, black and white film, fish head film, KB film, customized printed film,

etc.

l Stainless steel protective film origin classification: domestic

film and imported film.

l Stainless steel protective film pasting classification: oil film,

water glue film, self-adhesive film, electrostatic film, etc.

Stainless Steel Protective Film Material

Types

Stainless steel protective film is a

material specially designed to protect stainless steel surfaces from damage and

corrosion. The common stainless steel protective film materials currently on

the market mainly include the following types:

l Synthetic resin: This material has moderate softness and hardness, and can effectively prevent stainless steel from mechanical damage, such as

chemical substances or scratches. In addition, synthetic resin protective films

protect against damage from UV radiation.

l Polyethylene: Polyethylene is a transparent material with

excellent toughness and wear resistance. It effectively protects stainless

steel surfaces from damage such as chemical corrosion and abrasions, while also

protecting against the effects of ultraviolet radiation.

l Polyurethane: This material is relatively hard and is mainly used

to protect the surface of stainless steel from heavy machinery and equipment.

It can effectively prevent the surface from being damaged by heavy pressure,

scratches or impacts.

How To Choose the Appropriate Stainless

Steel Protective Film Material?

Stainless steel protective films made of

different materials with different advantages and disadvantages in different

occasions. Here are some factors to be considered when choosing a material:

l Usage environment:

Different environments damage the surface of stainless steel in different ways.

Some environments may be sensitive to chemical corrosion, so you need to choose

a protective film that can effectively prevent chemical corrosion; some

environments may have heavy objects rubbing or extruding, so you need to choose

a protective film with higher hardness.

l Use period: Protective films

made of different materials have different service periods. It is necessary to

select the appropriate protective film material based on the actual use time.

l Effect of use: Protective films

made of different materials have different application ranges and protective

effects. When choosing materials, you need to comprehensively consider the

effect and economy, and choose the one that best suits your needs.

Main Points of Using Protective Film in the Production and Processing

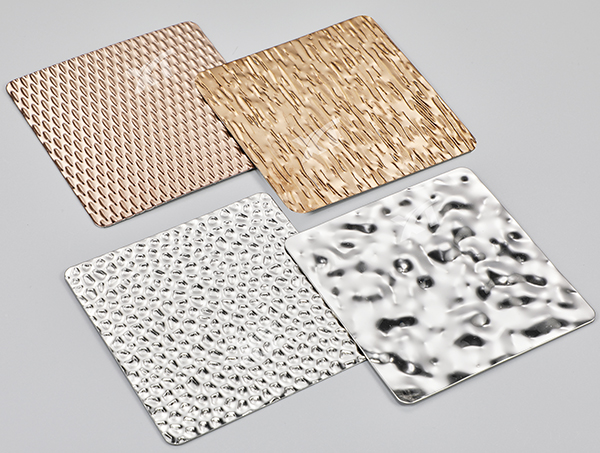

l Ordinary stainless steel protective films: only used to protect the surface of stainless steel, such as satin

finish, brushed finish, mirror BA finish. Normally the satin and brushed finish

surfaces need to be covered with a protective film with a

slightly higher viscosity, usually above 70 viscosity. But BA finish surface

requires with a lower viscosity.

l Stainless steel protective films for laser (laser film): usually used in laser cutting and processing of stainless-steel sheets.

Under normal circumstances, stainless

steel sheets used for laser cutting cannot use ordinary films, but need to use

special stainless steel laser films; laser cutting processes include carbon

dioxide laser cutting and fiber optic cutting machines, and fiber optic

machines need to be protected by fiber optic films. In addition, the current

rapid development of stainless-steel laser cutting and processing equipment,

laser cutting equipment with different wattages and produced by different

manufacturers will also have certain differences in the coating of stainless-steel sheets. Special attention needs to be paid to the fact that the thickness

and viscosity of laser equipment films with different wattages need to be

adjusted accordingly according to the processing equipment. It is also

necessary to apply laser films of different viscosities or fiber-specific films

to different stainless-steel surfaces.

l Stretch stainless steel protective films: The film material needs to be stretched or stamped later.

The main feature of stretch film is that

the protective film itself has a certain degree of toughness and is suitable

for stretching or stamping. In addition, the appropriate viscosity and

thickness of the stainless-steel film are also key points for laminating

stretched and stamped parts. If the viscosity is not enough, the film will

easily blow up during the production process, failing to protect the stainless-steel surface; but if the viscosity is too high, it will be difficult to tear

off the film of the stainless-steel product after stretching and stamping,

requiring a lot of manpower to tear off the film.

The main feature of stretch film is that

the protective film itself has a certain degree of toughness and is suitable

for stretching or stamping. In addition, the appropriate viscosity and

thickness of the stainless-steel film are also key points for laminating

stretched and stamped parts. If the viscosity is not enough, the film will

easily blow up during the production process, failing to protect the stainless-steel surface; but if the viscosity is too high, it will be difficult to tear

off the film of the stainless-steel product after stretching and stamping,

requiring a lot of manpower to tear off the film.

l Filming methods for special requirements: single-sided film, double-sided film, double-layer film, and spaced

film.

What Should We Consider About Protective Films for Colored SS Sheets?

When applying the film, it must be flat

to avoid bubbling, wrinkling, etc. If the requirements are particularly high,

you can ask the factory to apply a double-layer protective film.

In order to avoid the protective film

falling off and being unstable, you can use a protective film with a slightly

higher viscosity in winter and a protective film with a slightly lower

viscosity in summer.