How important is 8K mirror Sheet in

Decorative Industry?

An 8K mirror finish refers to a specific type of highly

reflective surface finish applied to stainless steel sheets. The "K"

in 8K stands for "kilogauss," which is a unit of magnetic flux density.

The term "8K" is commonly used in the context of stainless steel

finishes to denote a mirror-like surface that provides a high degree of

reflectivity and a polished appearance.

Depending on the customer's level of

fineness on the stainless steel surface, stainless steels such as 10k and 12k

are also available. The larger the number, the higher the surface fineness.

Where To Assemble 8K Mirror Finish

Stainless Steel Sheets?

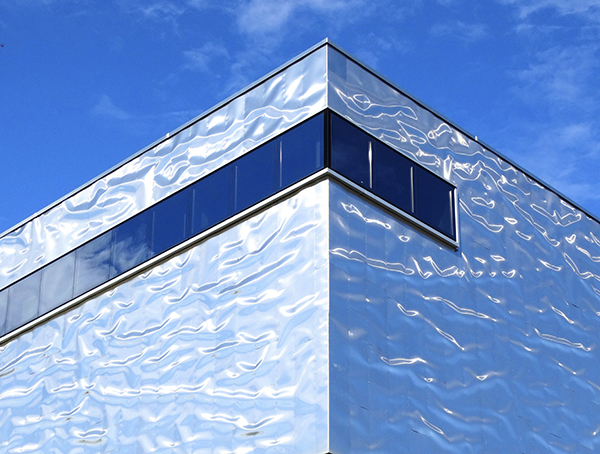

l Architectural and Interior Design: 8K mirror finish stainless steel sheets are frequently used in architectural projects and interior design applications. They can be incorporated into wall cladding, elevator panels, column covers, and decorative elements to enhance the aesthetic appeal of spaces.

l Decorative Panels and Trim: The high-gloss and reflective nature of 8K mirror finish sheets make them suitable for decorative panels, trim, and accents in both residential and commercial settings. They are often used to create modern and luxurious design features.

l Furniture: The premium appearance of 8K mirror finish stainless steel is well-suited for manufacturing furniture pieces, such as tables, cabinets, and countertops. The reflective surface adds a touch of sophistication to the overall design.

l Automotive Industry: In the automotive sector, 8K mirror finish stainless steel sheets may be used for interior trim, accents, and decorative features. The reflective surface can contribute to a sleek and modern appearance in vehicle interiors.

l Electronic Devices: Some electronic devices and appliances utilize 8K mirror finish stainless steel for exterior surfaces. This can include the casings of high-end audio equipment, home appliances, and electronic gadgets.

l Signage and Branding: The mirror-like appearance of 8K finish stainless steel is often employed in signage and branding applications. It can be used to create logos, lettering, and other elements that stand out with a polished and reflective surface.

l Food Processing and Pharmaceutical Equipment: The corrosion-resistant properties of stainless steel, combined with the high-gloss finish, make 8K mirror sheets suitable for certain equipment in the food processing and pharmaceutical industries. This includes surfaces that require easy cleaning and maintenance.

l Retail Spaces: Retail environments, especially those emphasizing a modern and upscale aesthetic, may incorporate 8K mirror finish stainless steel for displays, fixtures, and other design elements.

l Luxury Yachts and Cruise Ships: The marine industry often uses 8K mirror finish stainless steel for interior and exterior applications on luxury yachts and cruise ships. The reflective surface adds to the overall opulence and sophistication of the vessels.

l Art and Sculptures: Artists and sculptors may use 8K mirror finish stainless steel sheets to create contemporary art pieces or sculptures. The reflective quality can enhance the visual impact of the artwork.

Precautions For Processing 8K Mirror

Sheets

Processing 8K mirror panels requires careful attention to

detail and precision to ensure a high-quality result. There are some

precautions under consideration:

Ø Clean the environment: Ensure the working environment in a clean and dust-free workshop to prevent from settling on the mirror surface, tools and equipment are cleaned before use to avoid introducing scratches or contaminants to the mirror sheet.

Ø Gentle handling: Handle the mirror sheets with care to prevent scratches or damage through wearing clean and lint-free gloves to avoid leaving fingerprints on the surface.

Ø Use suitable cleaning solutions: When cleaning the mirror surface, use mild and non-abrasive cleaning solutions to avoid damaging the reflective coating.

Ø Avoid Abrasive Materials & Protective Film: Refrain from using abrasive materials, such as rough sponges or pads, and keep protective films on the surface until the final stages of processing to prevent scratches or smudges.

Ø Precision Cutting: Use precision cutting tools and techniques to achieve accurate cuts without causing chipping or cracking in the mirror panel.

Ø Temperature and Humidity Control: Maintain a controlled environment in terms of temperature and humidity to prevent condensation or other environment factors that could affect the mirror surface.

Ø Quality Control & Regular Maintenance: Implement a rigorous quality control process at various stages of processing to identify and address any issues promptly. Keep regular maintenance on processing equipment to ensure that it operates smoothly and does not introduce defects into the mirror panels.

Besides above precautions, pls follow the manufacturer’s

guidelines and specifications for specific recommendations.

Is There Any Solution For Scratched Mirror Panels?

1- The polishing method is used to repair the bright surface, and polishing wheels with different mesh sizes are used to repeatedly polish. Matte surface repair uses sandblasting, which requires special equipment.

2- If it is a brushed surface, special equipment is also required. No matter which of the above methods is used, the surface must be passivated. If it is a slight scratch, you can use polishing wax to polish the stainless steel countertop if it is a mirror surface, or you can use a wire drawing machine to draw the stainless steel surface if it is brushed.

3- If there are dirt marks on the surface,

grind it with a little flour and replace it with edible flour on a dry

countertop. Wipe it repeatedly with a dry rag to make it as bright as new. Do

not use a wire brush to clean the stainless steel surface, and do not leave a

wet sponge or cloth on the stainless steel surface to avoid stain accumulation.

What are The Difference Between Brushed Sheets And 8k Sheets?

Different Concepts

Stainless

steel brushed sheet refers to the stripe-like texture effect on the surface of

stainless steel. It is the most common and widely used stainless steel surface

processing technology. After the stainless steel plate with matte surface has

been brushed, there are traces of texture on the surface, but there is no

uneven feeling to the touch. Brushed stainless steel is more classy than

ordinary 2B stainless steel, because the surface brushing treatment can reflect

the texture of the metal material. The main types of textures include straight

lines, random lines, corrugations and threads.

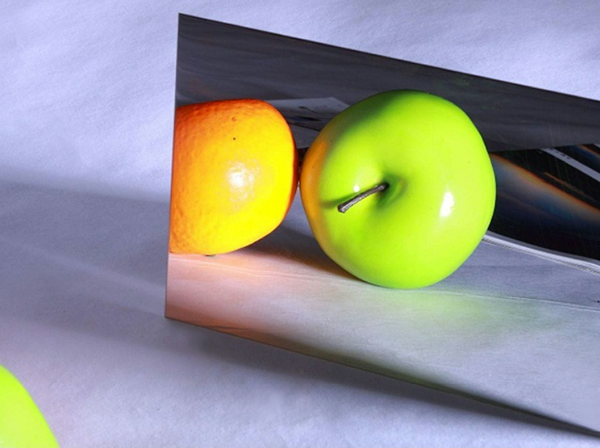

Stainless

steel mirror panel refers to polishing the stainless steel plate surface with

abrasive liquid through polishing equipment. Iron red powder, nitric acid, and

water are used as the grinding medium, and the surface formed by grinding with

wool felt makes the surface of the plate as clear as a mirror.

Different

uses

Brushed

sheets are commonly used in various architectural, industrial, and decorative

applications due to their unique finish, such as Kitchen appliances, signage,

household fixtures and architectural elements. Brushed stainless steel has a

distinctive look with fine parallel lines created by brushing the metal

surface.

8K

mirror sheets are widely used for architectural and interior design, decorative

panels and trim, furniture, automotive industry, retail spaces, etc. where

requires high lights mostly.

Different Physical Properties

The

brushing process will lose the thickness of the stainless steel plate to a

certain extent, generally 0.1~0.2mm. In addition, since the human body,

especially the palms, has a relatively strong secretion of oil and sweat, the

brushed stainless steel plate will leave obvious fingerprints when frequently

touched by hand, and needs to be scrubbed regularly.

The brushed plate is an effect formed on

the surface of the original surface through friction with the high-speed

abrasive belt running through the conveyor belt. Mirror stainless steel is a

surface effect formed by polishing with a linen wheel and a polishing wheel. It

is also called 6K plate in the industry.

The

mirror panel is made of iron red powder, nitric acid, and water as grinding

media, and the surface is formed by grinding wool felt. The effect is

comparable to that of mirrors used by people. The surface of the brushed board

is uneven, with slight pear marks. The pear marks appear bright, and there is

no image on the surface.