What

Is Pattern Finish Decorative Sheet?

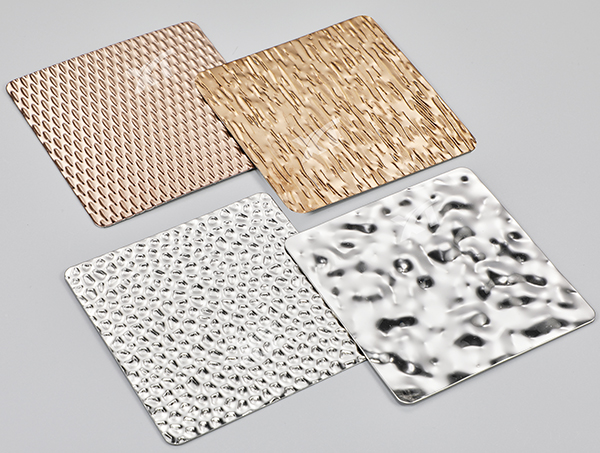

A pattern finish stainless steel sheet has undergone a surface treatment to introduce a specific pattern or texture. This finish is often applied for decorative purposes in architectural, interior design, and industrial applications. The pattern finish adds visual interest and texture to the stainless steel, making it more versatile for various aesthetic and functional uses.

Different methods are used to achieve pattern finishes on stainless steel sheets, and the choice of finish depends on the desired appearance and application. Some common types of pattern finishes include:

Ø Embossed Finish: This involves creating raised patterns or designs on the surface of the stainless steel sheet. The patterns can range from simple textures to more intricate designs, providing a three-dimensional effect.

Ø Brushed Finish: Also known as a satin or matte finish, brushing involves rubbing the stainless steel surface with abrasive materials to create a textured, non-reflective finish. This finish is often chosen for its contemporary and elegant appearance.

Ø Perforated Finish: In this finish, the stainless steel sheet is perforated with holes in a specific pattern. This not only adds a decorative element but also serves functional purposes such as improved airflow or visibility.

Ø Textured Finish: Various mechanical or chemical methods can be used to create textured finishes on stainless steel sheets. This may include hammering, rolling, or using acid treatments to achieve specific textures.

Ø Colored or Coated Finishes: Some pattern finishes may involve applying colored coatings or finishes to the stainless steel surface, enhancing its appearance and providing additional design options.

Pattern finish stainless steel sheets are

commonly used in a variety of applications, such as interior and exterior

decoration, wall cladding, elevator panels, kitchen appliances, and more. These

sheets offer the corrosion resistance and durability associated with stainless

steel, combined with the aesthetic appeal of the chosen pattern or texture. The

specific pattern finish chosen can significantly impact the overall look and

feel of the stainless steel in a given application.

Today, we

learn about the stainless steel embossing process

The stainless steel embossing process is a method of processing the surface of stainless steel, which can add beauty and decoration to stainless steel products. This process uses molds to emboss stainless steel plates, which can be made into various shapes and patterns, such as grids, patterns, geometric shapes, etc., to achieve the purpose of enriching surface effects.

The specific process of this process is: first select a suitable stainless steel plate, polish and clean its surface to make it smooth and smooth, and ensure that there are no impurities and stains. Then place the stainless steel plate on the embossing machine, and select the corresponding mold for embossing as needed. During the embossing process, attention needs to be paid to controlling the pressure and speed to ensure the clarity and consistency of the patterns and patterns. After embossing is completed, surface treatment, such as painting, polishing, etc., is required to increase its durability and beauty.

The

stainless steel embossing process is highly decorative and practical, and can

be used in various stainless steel products, such as wall decorative panels,

elevator doors, furniture, kitchen and bathroom supplies, and other fields. At

the same time, the advantages of this process include high processing accuracy,

diverse patterns, and strong durability, so it has been widely used and

promoted in the market.

How To Make The Patterns Of Stainless Steel Plates?

v Embossing method

v Embossing method

This is also the most common method currently and one of the cheaper methods. Patterns are obtained by applying pressure using fonts, molds or round rollers to force local materials to plastically deform. Pressure processing includes stamping method, static pressing method or rolling method, etc. There is internal stress after imprinting, and its stress and deformation decrease according to the above methods. The embossing depth can be deep or shallow according to the tensile properties of the mold and the stainless steel plate, becoming a permanent mark with stress. The stainless steel embossed plate is processed by this process.

v Chemical Corrosion Method

Through various printing techniques or photographic plate making, the surface of the stainless steel plate is first covered with a resist film with a pattern, and etched in an appropriate corrosive liquid. After the film is removed, a pattern with higher precision is obtained. This method is suitable for large quantities. Production. Our commonly used money flower panels and black titanium marble are made in this way.

v Engraving And Milling

Use mechanical equipment, such as engraving machines and copy engraving machines, to manipulate rotating tools for milling or hand engraving. This method can only engrave on flat steel plates and is easy to perform deep milling. This method is more expensive but has a strong three-dimensional effect.

v Sand Blasting Method

Compressed air is used to spray high-speed emery on the surface of the stainless steel plate blocked by the pattern template to form a sand surface pattern. The surface produced by the sandblasting method is rough, and it is difficult to spray thin strips. The depth is generally not greater than 0.08mm.

v Electrochemical Etching

Use an auxiliary electrode in an appropriate electrochemical etching solution to corrode the surface of the stainless steel plate that has been covered with a patterned resist film to obtain an etched pattern. The etching speed is faster and the pattern formed is deeper, requiring the use of specialized instruments and equipment.

Of course, in addition to the above commonly used ones that directly form patterns on the surface of stainless steel, there are also thermal transfer and lamination boards that are slowly being accepted by the market. Moreover, with the development of stainless steel processing technology, new processes will continue to emerge, and stainless steel plates will become more and more popular.

What Are Water Ripple Plates?

Water ripple plates, known as corrugated plates, are made of stainless steel plates that are mechanically rolled and punched to form an uneven plane. Patterns are stamped on the stainless steel plates. Through this production method, the stainless steel plates can be made into planes of different shapes, such as millet grains, rhombus, hexagon, leather pattern, square and other shapes.

And the stamped shape can be embossed according to the customer's needs. However, from the current point of view, the decorative development trend of stainless steel water corrugated boards is very powerful, especially the concave and convex surfaces of the water corrugated boards pressed out by mirror panels will produce reflective effects, coupled with trendy color combinations, the originally lifeless stainless steel can instantly be transformed into the most beautiful thing among decorative panels!

Why Does Water Ripple Plate Become So Popular?

The reason is that its surface can flow

like water, and through the refraction of light, it can form blue waves like

water ripples. This also makes it more commonly used in the decoration of

ceilings.

The reason is that its surface can flow

like water, and through the refraction of light, it can form blue waves like

water ripples. This also makes it more commonly used in the decoration of

ceilings.

Water corrugated stainless steel plate continues the corrosion resistance, acid resistance, fire resistance, environmental protection and other stainless steel characteristics of stainless steel. It is durable, impact resistant and does not fade! Of course, if you have sufficient financial resources, you should choose a better stainless steel model, such as 304 stainless steel, because the environment of each application is different and the problems caused are also different.

Compared with colored stainless steel

plates, the commonality of stainless steel embossed plates is that they have a

variety of colors to choose from. In addition to the big difference in

appearance, the patterns of embossed plates are much richer than those of

colored stainless steel plates, and their shapes are much better than those of

colored stainless steel plates. The colored stainless steel plates are novel,

and the mirror stainless steel embossed plates can visually create a 3D sense,

increase the spatial level and make the entire space transparent and clean, and

are easy to take care of. Just wipe it with a rag and the stains will be gone.